Upgrading to AGVs is one of the most effective ways to modernize internal logistics—but only if you choose the right model. With dozens of configurations available today, from compact material movers to ultra-heavy transporters capable of carrying more than 100 tons, the key is selecting a vehicle that truly fits your workflow.

This guide breaks down the essential factors that determine AGV performance in real production environments, helping you avoid under-sizing, bottlenecks, or costly redesigns later on.

Why the “Right AGV” Matters More Than You Think

Your AGV choice influences far more than transport efficiency. It directly affects:

Overall production throughput

Workplace safety

Energy consumption

Maintenance frequency

Equipment longevity

Long-term scalability

A vehicle that is too slow, too weak, or not suited to your operating environment can quickly become a source of delays instead of productivity.

Load Capacity: The Starting Point for Any AGV Selection

Load capacity is always the first specification to confirm, because it defines the AGV’s structural design, motor size, battery requirements, and speed.

Common Load Segments in Industrial AGVs

Light-duty (≤1–2 tons)

Ideal for electronics, small parts, assembly materials, packaging, and line-side totes.

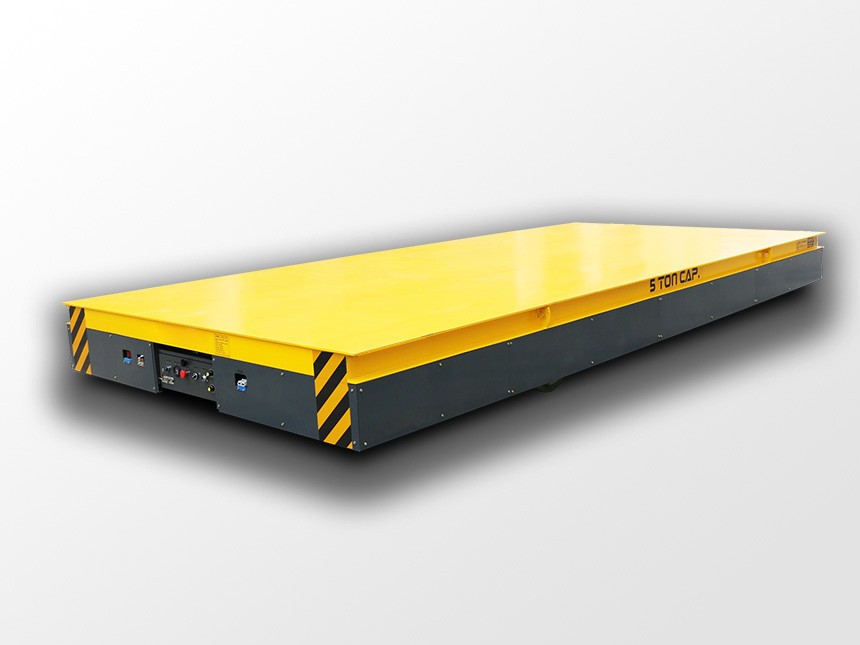

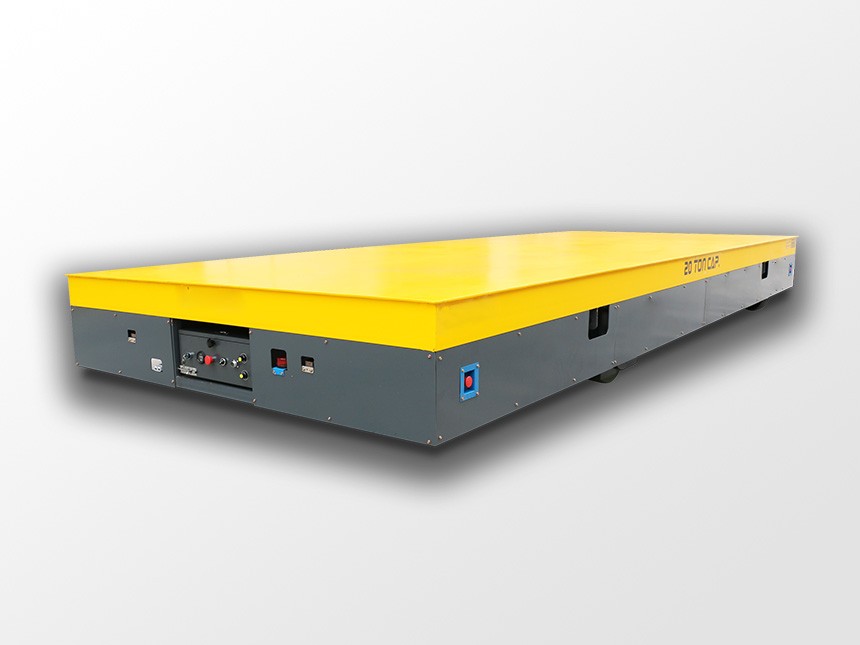

Medium-duty (2–10 tons)

Used for machining components, steel parts, warehouse pallets, and assembly fixtures.

Heavy-duty (10–100+ tons)

For molds, wind turbine components, metal coils, power-generation equipment, and large industrial assemblies.

ATN’s core strength lies in this segment, with precise and stable heavy-load transporters.

How to Determine the Load You Actually Need

Calculate total transport weight, including:

Product/material weight

Pallet or fixture

Any top module (lift table, roller deck, turntable, etc.)

Safety margin (typically 20–30%)

Example:

Material: 6 tons

Pallet: 1 ton

Lifting module: 0.8 ton

→ Actual load: 7.8 tons

→ Recommended AGV rating: 10 tons

The safety margin protects motors, extends battery life, and keeps long-term operation stable.

Travel Speed: Finding the Right Balance Between Throughput and Safety

AGV speed isn’t simply “the faster, the better.”

Speed must be aligned with your load weight, aisle width, and traffic conditions.

Typical Speed Ranges

Light-duty: 1.0–1.5 m/s

Medium-duty: 0.8–1.2 m/s

Heavy-duty: 0.4–1.0 m/s

(Heavier AGVs run slower due to braking distance and stability requirements.)

What Affects the Speed You Should Choose

Width and straightness of aisles

Pedestrian activity

Number of turns or intersections

Floor quality

Hourly throughput targets

Congestion or equipment density

For long transport loops or time-critical operations, a higher-speed model may be necessary to maintain cycle time.

Battery Systems: Powering AGVs for Real Operations

Battery technology controls how long your AGV runs, how often it charges, and how much maintenance is required.

Lead-Acid (Traditional)

Pros:

Low cost

Stable, proven

Suitable for light workloads

Cons:

Long charging times

Shorter lifespan

Requires regular maintenance

Best for simple operations with low duty cycles.

Lithium-Ion (Modern Standard)

Pros:

Fast charging

High energy density

Long service life

Zero daily maintenance

Strong performance in 24/7 production

Cons:

Higher initial investment

Most modern AGVs use lithium batteries because they offer predictable performance and excellent ROI.

Supercapacitors (Ultra-Fast Charging)

Pros:

Charge in 1–5 minutes

Extremely long cycle life

Ideal for workflows with short stops

Cons:

Lower energy storage

Suited for short, repetitive tasks

Supercapacitor AGVs are common in high-frequency shuttle systems.

Operation Mode & Workflow Integration

The right AGV must match not only your load but also how your production line actually works.

Levels of Automation

Manual / Remote-control — simple movement, low cost

Semi-automated — guided operation with sensors

Fully automated — integrated with MES/WMS/ERP for end-to-end automation

Top Modules That Change AGV Functionality

Lifting platforms

Roller or conveyor decks

Rotating tables

Robotic interfaces

Forklift attachments

Custom fixtures

In many projects, the module on top of the AGV is just as important as the AGV chassis itself.

Environmental Compatibility: Don’t Overlook These Factors

A well-performing AGV must match the physical conditions of your facility.

Flooring

Concrete

Epoxy

Steel plates

Grating

Uneven surfaces

Heavy-duty AGVs may need custom suspension or reinforced drive systems.

Temperature Requirements

Cold storage down to –25°C

High-temperature environments near furnaces

Cleanrooms requiring anti-static components

ATN supplies AGVs specifically engineered for these conditions.

Aisle Width & Turning Radius

The vehicle must safely navigate:

Narrow aisles

Sharp turns

Multi-intersection routes

Loading/unloading points

Heavy AGVs often rely on omni-directional or multi-steering axles for tight layouts.

Navigation: Matching Technology to Your Layout

You can choose from several navigation systems, each suited to different workflows:

Magnetic tape: cost-effective for stable routes

QR/visual: flexible and easy to update

Laser (LIDAR): high precision, easy to reconfigure

Inertial: excellent for harsh or vibration-heavy environments

Hybrid: combines strengths for complex, multi-zone layouts

Navigation is a long-term decision—choose for accuracy, scalability, and maintainability.

How to Build a Complete AGV Requirement Sheet

Before purchasing, prepare a clear technical brief. Key items include:

Load weight & dimensions

Center of gravity

Route layout (or CAD drawing)

Required cycle time

Navigation preference

Charging strategy

Environmental details

Safety requirements

Integration needs (MES, sensors, conveyors)

Future scalability

ATN engineers often work with customers directly to create this document during the planning phase.

ATN AGV Solutions for Every Industry

ATN provides:

Light, medium, and heavy-duty AGVs

Trackless and track-guided transporters

Omni-directional heavy carriers

Cleanroom and cold storage AGVs

Fully customized AGV designs

Complete automated logistics engineering

Our solutions support customers in more than 48 countries across automotive, electronics, steel, energy, heavy equipment, and general manufacturing.

Learn more: https://www.atnagv.com

Final Thoughts

Selecting the right AGV is far more than choosing a model from a brochure.

It requires understanding your load characteristics, route demands, battery strategy, navigation needs, and environmental limitations.

When done correctly, a well-matched AGV system can dramatically increase productivity, reduce labor dependency, and create stable, scalable logistics for years to come.

English

English 简体中文

简体中文