When companies begin planning an AGV project, one of the first questions that comes up is: “Which navigation method should we choose?”

It sounds like a technical detail, but in reality it affects almost everything—route accuracy, obstacle behavior, installation cost, and even how easily the system can adapt to future layout changes.

Below is a straightforward, experience-based explanation of the most common AGV navigation methods and how they perform in everyday industrial environments.

Why Navigation Matters More Than Most People Realize

An AGV’s navigation system determines:

How precisely it knows where it is

How it follows a route

How it reacts when something blocks its path

Whether the layout can be changed easily

How stable it operates over long periods

Different navigation technologies serve very different types of workflows, so choosing the right one is a major factor in building a reliable system—not just an engineering preference.

Magnetic Tape Navigation: Simple, Reliable, and Budget-Friendly

Magnetic tape is one of the earliest and most widely used navigation methods. Many factories still prefer it because it’s easy to install and extremely predictable.

How it works:

A magnetic strip is placed on the floor, and the AGV uses onboard magnetic sensors to follow it.

Why people like it:

Low cost compared to other methods

Straightforward installation

Stable performance once the route is set

Ideal for repeating the same movement thousands of times

Where it struggles:

Changing a route means physically replacing tape

Heavy forklifts or pallets can damage it

Not ideal for dusty, oily, or high-traffic industrial floors

For environments with steady workflows—assembly lines, fixed warehouse loops—magnetic tape still performs well.

QR Code / Visual Navigation: Flexible and Easy to Update

QR-based navigation is popular in facilities that need more flexibility than tape without moving to more complex systems.

How it works:

QR markers are placed along the floor. The AGV reads each marker with a camera and uses it to calculate position and direction.

Strengths:

Very quick to adjust routes

Low cost

Easy to expand or reconfigure

Works well for medium-accuracy requirements

Limitations:

Lighting conditions matter

Dirt, dust, and spills affect readability

Less accurate than laser-based navigation

This method works best in electronics assembly, general warehouses, or environments that occasionally adjust aisles and stations.

Laser (LIDAR) Navigation: The High-Precision Workhorse

Many factories upgrading to modern AGVs choose laser navigation because it provides accuracy and flexibility without heavy infrastructure modifications.

How it works:

The AGV emits laser beams. Reflector targets placed throughout the facility return signals.

Software then triangulates the AGV’s exact location—constantly, in real time.

Advantages:

Very high accuracy

Excellent for complex or long routes

Easy to modify paths through software

Strong obstacle detection and mapping

Drawbacks:

Higher cost than tape or QR

Reflectors must be installed and maintained

Performance may be affected by extreme dust or steam

Laser navigation is commonly used in automotive plants, large manufacturing halls, precision workshops, and anywhere high repeatability is required.

Inertial Navigation: Built for Harsh and Demanding Environments

Inertial systems are less talked about publicly but widely used in heavy-industry applications.

How it works:

The AGV uses gyroscopes and accelerometers to track movement and corrects its position with RFID tags placed in the floor.

Why it’s valuable:

Very stable over long distances

Excellent performance in dusty, oily, or vibrating environments

Minimal visible infrastructure

What to consider:

Requires installing RFID tags

Needs careful calibration

Typically more expensive than tape or QR

This makes inertial navigation a strong choice for metalworking, foundries, machining halls, or any location with tough environmental conditions.

Hybrid Navigation: When One Method Isn’t Enough

More factories are now using combinations of navigation modes—for example:

Laser + magnetic

Laser + vision

Vision + SLAM

Why hybrid systems are rising:

Higher overall accuracy

Better obstacle handling

Flexibility across different zones

Smooth transitions between fixed and flexible areas

For mixed workflows or facilities that grow in phases, hybrid navigation provides long-term adaptability.

Quick, Practical Comparison

| Navigation Type | Accuracy | Cost | Flexibility | Best Use Case |

|---|---|---|---|---|

| Magnetic Tape | Medium | Low | Low | Stable, repetitive routes |

| QR / Visual | Medium | Low | Medium | Light-duty, flexible layouts |

| Laser (LIDAR) | High | Med–High | High | Complex, high-precision paths |

| Inertial | High | Med–High | Medium | Harsh or heavy-industry environments |

| Hybrid | Very High | Med–High | Very High | Mixed workflows, long-term scalability |

Choosing the Right Navigation Method

Here are the factors that matter most in real projects:

Route complexity:

Simple routes → tape / QR

Complex paths → laser / hybridAccuracy requirements:

Light tasks → tape / QR

Precision tasks → laser / inertialBudget:

Lower budgets → tape / QR

Flexible investment → laser / hybridEnvironmental conditions:

Dust, heat, vibration → inertial

Cleanrooms → laser / hybridFrequency of layout changes:

Frequent → QR, laser, hybrid

Rare → tape, inertial

A good AGV supplier will walk through each of these with you before recommending a specific method.

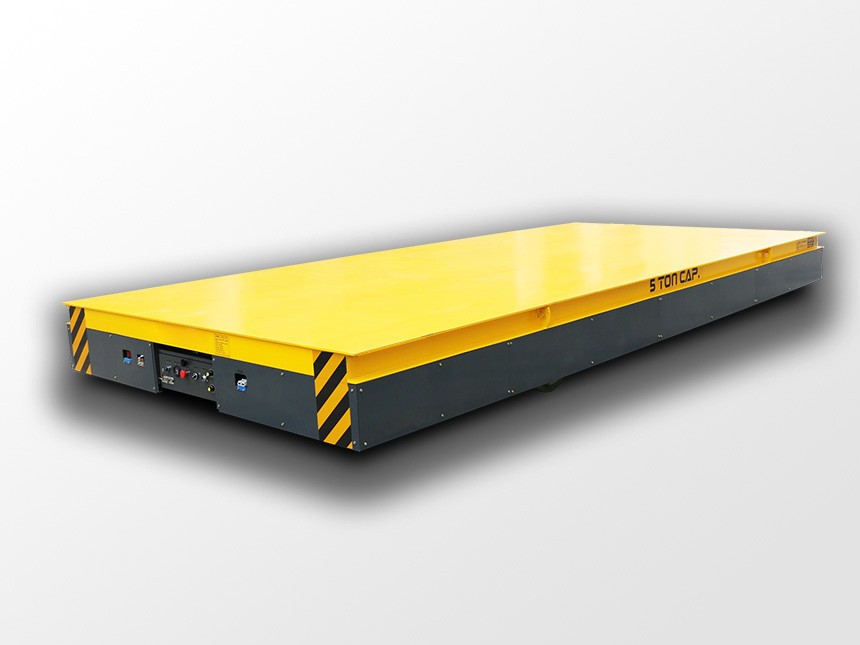

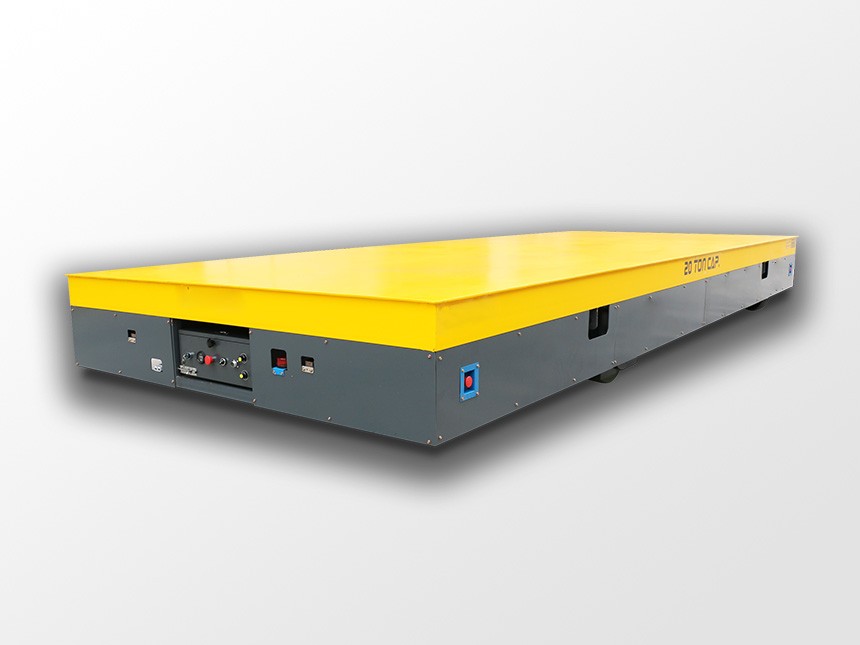

ATN’s Navigation Options for AGV Projects

ATN (Xinxiang Aotenng Automation Equipment Co., Ltd.) supports multiple navigation technologies and custom integrations, including:

Magnetic tape

QR / visual navigation

Laser (LIDAR) navigation

Inertial systems

Hybrid combinations for complex factories

With extensive experience in automotive, electronics, power equipment, metal processing, and global logistics, ATN provides AGV solutions in more than 48 countries.

More information: https://www.atnagv.com

Final Thoughts

There is no “best” navigation system for every situation—only the right one for your workflow.

Magnetic tape remains cost-effective for stable operations, QR offers flexibility on a budget, laser is ideal for precise and evolving routes, and inertial systems thrive in harsh conditions. Hybrid approaches combine strengths for long-term scalability.

By understanding what each method offers, companies can choose navigation that delivers accuracy, stability, and efficiency—now and in the future.

English

English 简体中文

简体中文