In the last decade, factories and warehouses have been adopting mobile robots at a pace few people expected. Two technologies tend to dominate discussions—AGVs and AMRs. At first glance, they look similar: both move materials without drivers and both promise safer, more automated operations. But once you look at how they navigate and how they behave on the floor, the differences become quite clear.

Choosing the right one can have a major impact on workflow stability, cost, and future scalability. The following comparison is written from a practical point of view—what actually matters when these systems go into real industrial environments.

Understanding AGVs: Controlled Paths and High Predictability

AGVs (Automated Guided Vehicles) follow fixed routes. Their paths are usually defined by magnetic tape, reflector targets, wire guidance, QR codes, or combinations of these methods.

Because AGVs repeat the same motion every cycle, they’re extremely consistent. That’s why many factories with stable workflows still rely heavily on them.

You will find AGVs in environments such as:

Automotive assembly

Electronics manufacturing

Heavy-equipment transport

Cleanrooms and cold storage

Power-generation component handling

Line-side delivery in structured production lines

Their biggest strengths are reliability, precision, and a long-established safety record.

Understanding AMRs: Flexible Navigation for Changing Spaces

AMRs (Autonomous Mobile Robots) represent the more “intelligent” category of mobile robots.

Instead of following fixed routes, AMRs navigate using sensors, cameras, LiDAR, SLAM, and onboard computing. They make decisions on the fly—detecting obstacles, choosing alternate paths, and adjusting movement based on real-time conditions.

They’re well suited for facilities that change layouts frequently or where material movement is less predictable.

Key characteristics of AMRs include:

Quick deployment with minimal infrastructure

Adaptive route adjustments

Smart obstacle avoidance

High flexibility in dynamic environments

AGV vs. AMR: How They Differ in Practice

Navigation

AGVs stay on structured, predefined paths. If an obstacle blocks the track, the vehicle stops and waits.

AMRs, on the other hand, recalculate their path, move around the obstacle, and continue.

Safety

Both technologies use scanners and safety sensors, but AMRs generally rely on more advanced perception tools such as multi-layer LiDAR and 3D obstacle detection.

AGVs, however, have the advantage of extremely stable, predictable behavior—a key requirement in production-heavy industries.

Cost and ROI

AGVs typically cost less upfront and require simple maintenance.

AMRs cost more initially due to their richer sensor suite, but they save time during installation because no tape or reflectors need to be laid on the floor.

In predictable workflows, AGVs tend to provide faster ROI.

In fast-changing warehouse-type environments, AMRs usually outperform.

Scalability

AGVs scale well along defined routes—especially when production volumes increase or more vehicles are added to the same loop.

AMRs scale best in facilities where new stations appear frequently or where the layout changes several times a year.

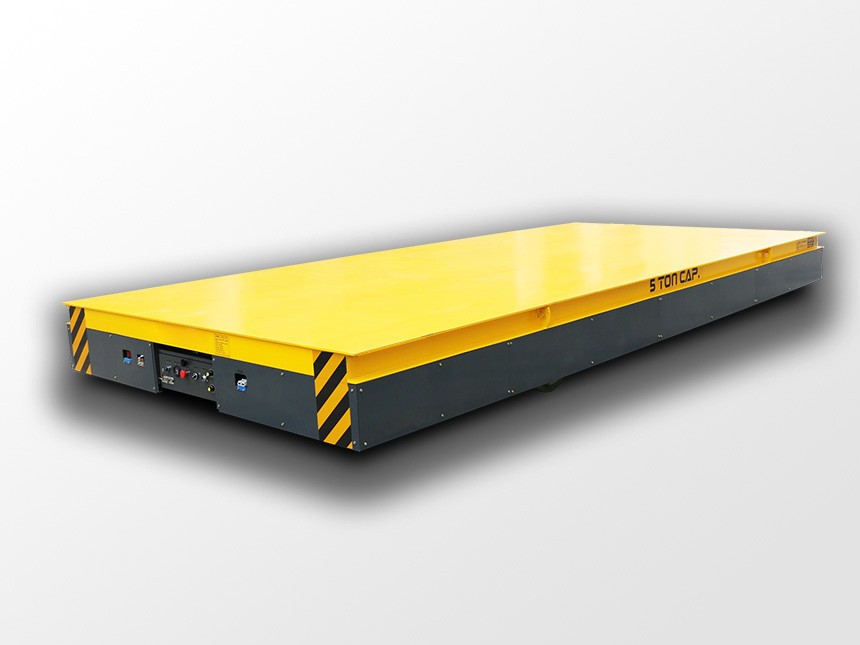

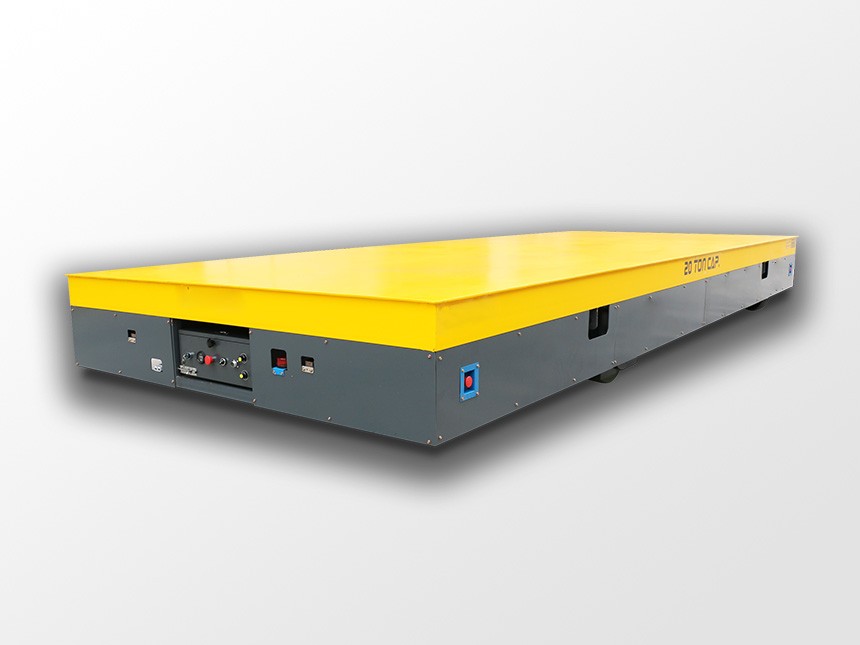

Payload Capacity

This is one of the clearest differences.

AGVs can be engineered to carry extremely heavy loads—10 tons, 50 tons, even over 100 tons for specialized applications like wind-turbine components or steel molds.

AMRs generally focus on lighter tasks, typically between 100 and 2,000 kg.

For heavy industry, AMRs rarely replace AGVs.

When an AGV Makes More Sense

AGVs tend to be the better choice in environments where:

Processes are repetitive and structured

High accuracy is needed at fixed drop-off points

Payloads exceed the limits of AMRs

Predictability and safety are non-negotiable

Maintenance must stay straightforward

Cost control matters over long-term operation

Industries like automotive, electronics, steel processing, energy equipment, and pharmaceuticals often find AGVs to be the most reliable foundation for logistics automation.

When an AMR Is the Better Fit

AMRs excel when:

The facility layout changes often

Routes need to be flexible

Traffic is dynamic and unpredictable

Deployment must be quick with minimal modification

Loads are light to medium

The environment resembles a warehouse or distribution center

This is why AMRs are extremely popular in e-commerce logistics and flexible storage systems.

Using Both: Hybrid Fleets Are Becoming Common

Many advanced facilities now combine AGVs and AMRs.

AGVs handle the stable, heavy, repetitive transport tasks.

AMRs take on lighter jobs, packaging movement, and unpredictable routing.

Fleet management software keeps both vehicle types coordinated, ensuring they operate safely on shared paths.

This hybrid approach gives companies the benefits of both stability and flexibility.

Why AGVs Still Dominate Industrial Applications

Even though AMRs are growing rapidly, AGVs remain the preferred option in harsh or high-precision industrial environments because:

They support much higher payloads

Their motion is extremely stable

Maintenance is simpler

Navigation is consistent

They integrate smoothly with production lines

They deliver strong long-term cost efficiency

In other words, AGVs are built for industrial durability, not just intelligent navigation.

ATN’s AGV Solutions for Global Manufacturing

ATN (Xinxiang Aotenng Automation Equipment Co., Ltd.) designs AGV systems for a wide range of industries, offering:

Standard AGV platforms

Heavy-duty AGVs from 10 to 100+ tons

Customized AGVs built to factory requirements

Cleanroom and cold-storage models

Trackless and track-guided transport systems

With deployments in more than 48 countries, ATN provides engineering support, system integration, and long-term service for global clients.

More information: https://www.atnagv.com

Final Thoughts

Choosing between AGVs and AMRs isn’t about which technology is “better.”

It’s about what your workflow actually needs.

AGVs deliver unmatched stability, load capacity, and long-term reliability—qualities that matter deeply in production-focused industries.

AMRs offer the flexibility required in dynamic warehouses or facilities that change frequently.

For many manufacturers, the ideal solution is not one or the other, but a thoughtful combination of both.

English

English 简体中文

简体中文