In the past few years, one of the biggest shifts inside factories hasn’t been a new robot arm or a new production line—it’s the way materials move. As manufacturers accelerate automation and digitalization, many are discovering that Automated Guided Vehicles (AGVs) can solve several long-standing workflow challenges that manual methods simply can’t handle well anymore.

AGVs are now used everywhere: assembling cars, moving semiconductor wafers, transporting heavy steel components, and even navigating cold-storage facilities. Their impact is surprisingly broad, and in many cases, more immediate than other forms of automation.

Below is a practical look at how AGVs raise productivity and why so many factories are making the switch.

Production Efficiency: Why It Has Become a Core Priority

Manufacturing today demands faster response times, greater flexibility, and highly stable quality. Yet the weakest link in many plants is still material handling.

Manual workflows often result in:

Irregular delivery timing

Increased labor dependency

Higher operating and training costs

Safety incidents in narrow aisles

Production delays caused by simple mistakes

When a plant adopts AGVs, the first change people notice is how steady and predictable the workflow becomes. Materials stop “waiting,” and so do the machines that rely on them.

Where AGVs Make the Biggest Difference

1. Non-stop, predictable material movement

Unlike a forklift that depends on the availability and attention of an operator, AGVs move continuously. They don’t pause for lunch breaks or shift changes, and they maintain the same driving pattern every single time.

This consistency helps production lines keep their rhythm. Even a few minutes saved per cycle can add up to hours of improved productivity each day.

2. Lower reliance on manual labor

Labor shortages are a serious concern in many industrial regions. Skilled forklift drivers are harder to find and even harder to retain.

AGVs ease this burden by handling repetitive transport tasks. Companies often reassign workers to areas that require judgment or inspection—places where automation does not yet replace human expertise.

3. Fewer handling mistakes

Misplaced pallets, incorrect deliveries, and rack damage are more common than most people admit. AGVs significantly reduce these incidents because they follow computer-defined routes, use precision sensors, and report each completed task digitally.

The result is a smoother production flow with fewer interruptions.

4. A safer working environment

Most on-site accidents involve moving equipment. Fatigue, blind spots, and coordination mistakes are typical contributors.

AGVs minimize these risks thanks to:

Laser scanners

Obstacle-detection sensors

Controlled speeds

Automatic emergency stops

Many factories adopting AGVs see accident rates drop almost immediately.

5. Real-time visibility of material movement

Because AGVs are digital devices, they automatically share data with MES, ERP, or WMS systems. Managers gain clearer insights into:

Which station needs materials

What has been delivered

Inventory status in real time

Bottlenecks forming on the floor

Data transparency becomes part of everyday operations instead of a special project.

6. Easy layout changes

Production layouts rarely stay the same for long. Instead of reinstalling conveyor systems, AGV routes can be adjusted through software updates. This is especially valuable for companies launching new product lines or adjusting workstation layouts.

Where AGVs Are Making a Strong Impact Today

Automotive & EV battery factories

They move engines, battery packs, car bodies, and support just-in-time delivery.

Electronics & semiconductor production

Cleanroom AGVs handle sensitive materials without contamination.

Heavy equipment & steel processing

Heavy-duty AGVs move molds, steel coils, and large structural parts—tasks that are difficult or unsafe for forklifts.

Warehousing and logistics

AGVs automate pallet movement, goods retrieval, sorting, and packaging feeds.

Food, pharmaceuticals, and cold-chain facilities

Because AGVs work reliably in controlled environments, they help ensure traceability and hygiene compliance.

Measurable Efficiency Improvements

Factories that adopt AGVs typically observe:

10–40% faster material movement

20–60% reduction in handling labor costs

Significantly fewer transport-related errors

Up to 90% fewer forklift-related accidents

AGVs are one of the simplest automation tools to justify in terms of ROI because the improvements show up quickly.

Why the Shift Toward AGVs Is Accelerating

Manufacturers increasingly value AGVs because they offer:

Scalability — easy fleet expansion

Predictable workflow — stable production timing

Cost efficiency — reduced manpower demand

Safety — fewer collisions and incidents

Digital compatibility — supports Industry 4.0 integration

For many modern factories, AGVs have transitioned from “optional automation” to a core operational system.

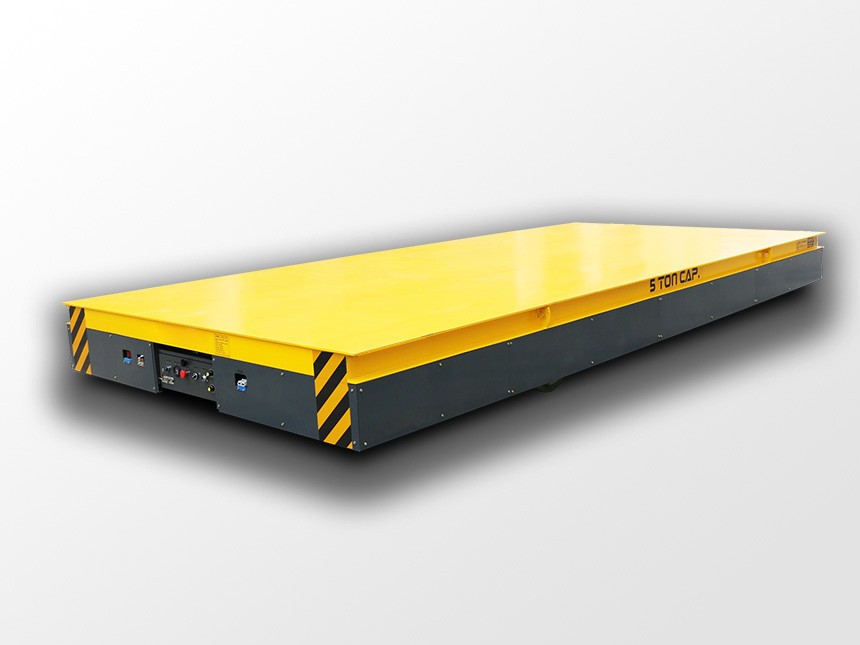

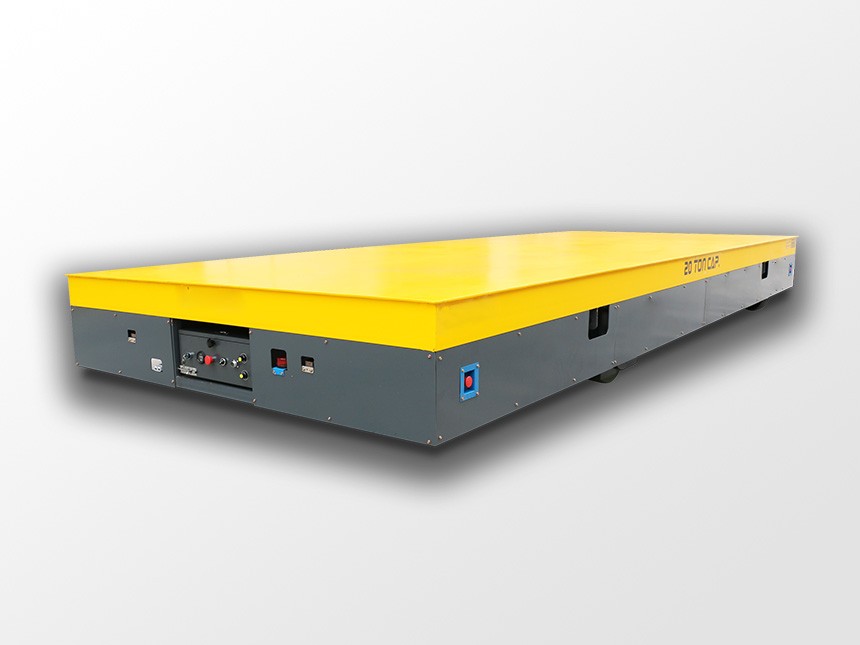

ATN AGV Solutions for Global Industries

With over a decade of engineering experience, ATN (Xinxiang Aotenng Automation Equipment Co., Ltd.) designs and manufactures AGVs for a wide variety of environments.

Their lineup includes:

Standard AGV platforms

Heavy-duty AGVs (10–100+ tons)

Cleanroom and low-temperature AGVs

Trackless and track-guided transport systems

Fully customized AGV solutions for unique applications

ATN’s AGVs are currently in use in more than 48 countries, serving sectors such as automotive, energy, electronics, and heavy industry.

More information is available at: https://www.atnagv.com

Final Thoughts

AGVs are fundamentally changing how factories operate. They bring consistency to material flow, remove repetitive labor, improve safety, and provide real-time visibility—all of which contribute directly to higher productivity.

Whether in a fast-paced electronics plant or a heavy industrial workshop, AGVs deliver improvements that are both measurable and long-lasting.

English

English 简体中文

简体中文