In recent years, many factories have begun rethinking how they move materials inside their facilities. Labor shortages, rising safety standards, and the demand for stable, repeatable production have pushed companies to look for alternatives to traditional forklifts and manual transport.

Under these pressures, Automated Guided Vehicles (AGVs) have gradually become one of the most practical tools for internal logistics—not because they are fashionable, but because they solve real operational problems.

This guide offers a clear, experience-based explanation of what AGVs do, how they work, and how manufacturers are using them to build more efficient and modern production environments.

What Exactly Is an AGV?

An AGV is essentially a battery-powered vehicle that moves materials on its own, following planned routes without human drivers. Depending on the facility, the route can be guided by several technologies, including magnetic tape, laser scanners, QR or visual markers, inertial systems, or a combination of multiple methods.

You’ll find AGVs in a wide range of environments—assembly workshops, warehouses, EV and automotive plants, cleanrooms, and even food or pharmaceutical production lines. The technology is well-established, but what makes AGVs valuable today is their reliability and predictability, especially for tasks that happen hundreds of times per day.

Typical characteristics of AGVs include:

Unmanned operation

Safe and predictable movement

Round-the-clock availability

Consistent point-to-point accuracy

Strong suitability for repetitive logistics tasks

In short, they move materials faster and with fewer interruptions than forklifts or manual carts.

How AGVs Actually Work

Although they may look simple from the outside, AGVs rely on several subsystems that work together to keep them running smoothly.

Navigation

Navigation determines how an AGV stays on its route. Plants with straightforward layouts often choose magnetic tape because of its low cost. More complex or fast-changing factories rely on laser navigation or visual markers. Large production lines sometimes combine multiple methods to increase stability.

Power System

Most modern AGVs are powered by lithium batteries. Some facilities use automatic charging stations so vehicles can recharge without human involvement, allowing genuine 24/7 operation.

Communication and Control

AGVs are coordinated by a central control platform, typically connected over Wi-Fi, industrial Ethernet, or a private 5G network.

This system assigns tasks, manages traffic, avoids collisions, and ensures that vehicles don’t interrupt one another—a crucial requirement once fleets grow in size.

Different Types of AGVs in Real Use

Because factories vary widely, AGVs come in a range of designs.

Towing AGVs

Used heavily in automotive and general assembly plants to pull trolleys or carts.

Forklift AGVs

An unmanned version of a forklift capable of pallet lifting, stacking, and warehouse operations.

Unit Load AGVs

Designed for moving boxes, racks, totes, and pallets where stability and accuracy matter.

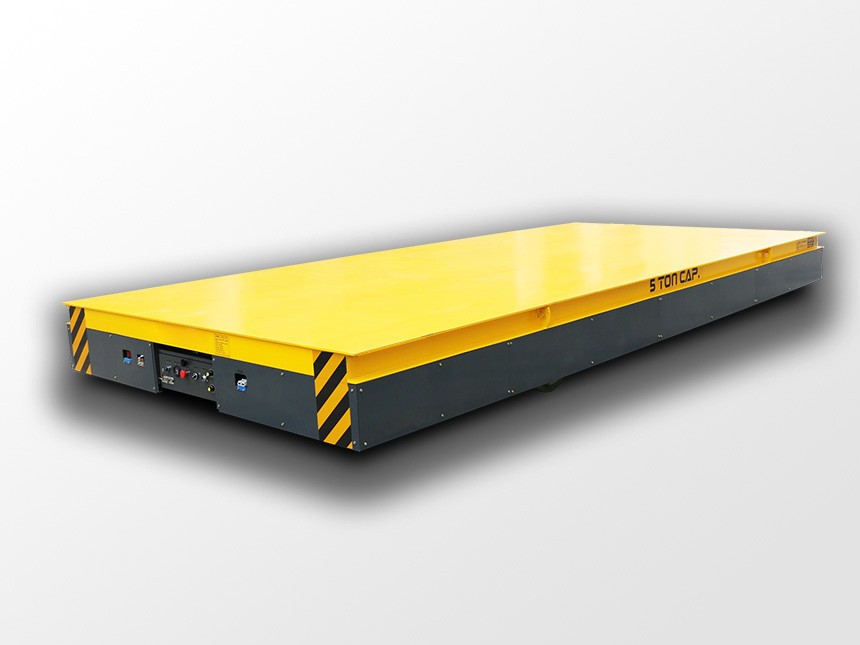

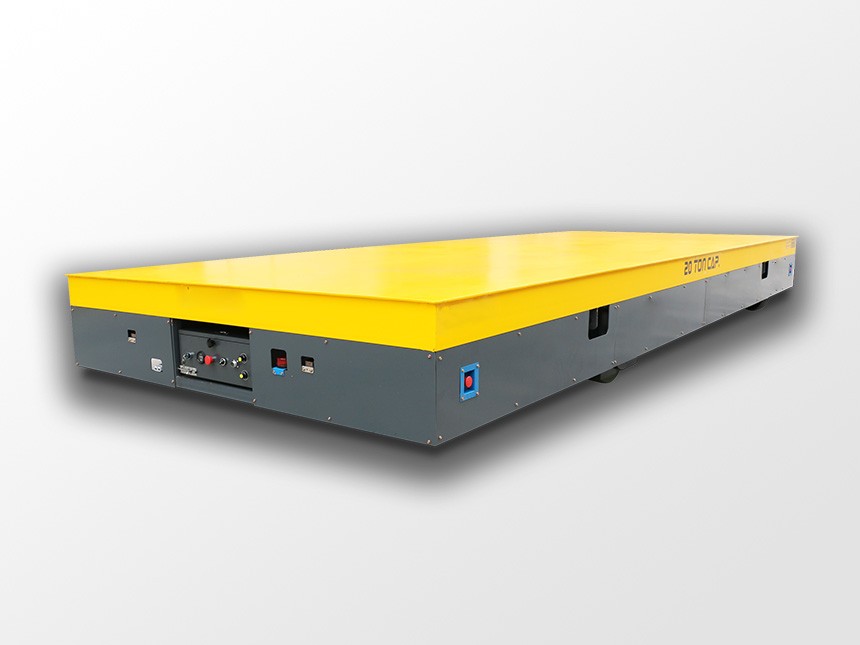

Heavy-Duty AGVs

These handle large components—sometimes 10 to 100 tons at a time.

Industries such as wind power, energy, steel, and mold manufacturing rely heavily on them.

Custom AGVs

Some environments require specialized designs—for example:

cleanroom AGVs, low-temperature applications, explosion-proof requirements, or vehicles with custom lifting and rotating platforms.

Why More Factories Replace Forklifts with AGVs

Factories don’t adopt AGVs for a single reason—it's usually a combination of safety, efficiency, and long-term cost planning.

Safety

AGVs are equipped with laser scanners, obstacle sensors, and emergency stop functions.

Removing forklifts immediately reduces collision incidents and insurance risks.

Efficiency and Stability

AGVs don’t take breaks, become distracted, or skip procedures. They deliver a level of consistency that’s difficult for human-operated transport to match.

Reduced Long-Term Costs

Labor shortages and turnover drive up training and operational expenses. AGVs offset these challenges while reducing error-related downtime.

Flexibility

Workflows change. Routes change. With AGVs, these adjustments happen through software—not construction work.

Integration with Factory Systems

AGVs can connect directly to MES, WMS, and ERP platforms, giving managers real-time visibility of inventory and movement.

Industries Where AGVs Are Common

Over the past few years, AGVs have expanded into nearly every industrial sector:

Automotive and EV manufacturing

Aerospace

Electronics & semiconductor cleanrooms

Pharmaceuticals

Food and beverage

Metallurgy and heavy equipment

Warehousing and distribution

Power generation and wind energy

Their tasks range from simple pallet transport to precision mold handling, line-side delivery, and staging materials for automated production lines.

How to Select the Right AGV System

Choosing an AGV is less about the vehicle itself and more about how it fits into your workflow. Key considerations include:

Load capacity — from lightweight totes to extremely heavy industrial components

Navigation type — based on complexity, route length, and frequency of layout changes

Operating environment — temperature, dust, slopes, aisle width, and cleanliness requirements

Level of automation — from single vehicles to a fully managed fleet

Safety features — sensors, limits, emergency systems

Customization — whether special lifting tools or platform modifications are required

A well-chosen AGV system should match your current needs while being expandable as production grows.

Why Many Manufacturers Select ATN AGV Solutions

ATN (AOTENENG) has been focusing on AGV engineering for more than a decade. Instead of offering only standard models, the company spends much of its time on customized AGV systems tailored to specific factories.

Their portfolio includes:

Standard AGVs

Heavy-duty AGVs for 10–100+ ton loads

Cleanroom-grade AGVs

Battery-powered and track-guided vehicles

Fully customized automation solutions

ATN’s equipment operates in over 48 countries, supported by remote diagnostics, onsite service, and long-term engineering assistance.

Conclusion

AGVs have moved far beyond being a niche automation tool.

They have become a practical foundation for safer, more consistent, and more scalable factory logistics. Whether a company handles small components or extremely heavy materials, AGVs help maintain smooth production flow and reduce operational risk.

For companies planning their next stage of automation or Industry 4.0 development, AGVs are no longer a luxury—they are a strategic investment.

For more information or customized planning, visit: www.atnagv.com

English

English 简体中文

简体中文