During the past decade, many factories have been talking about “Industry 4.0,” yet only a portion have truly begun reshaping their internal logistics. One interesting trend we’ve consistently observed—whether in automotive workshops, battery assembly lines, or traditional manufacturing plants—is the rapid increase in the use of AGVs (Automated Guided Vehicles).

Unlike large, expensive automation upgrades, AGVs solve a very simple but often overlooked problem: materials don’t move by themselves, and any stop in material flow eventually shows up as production delay.

Below is an honest, practical explanation of why AGVs are being adopted—not from theory, but from what real factories are running into on a daily basis.

1. What Does a “Smart Factory” Really Need?

People often describe smart factories using big terms—IoT, cloud platforms, 5G, digital twins. All of these matter, but day-to-day production depends on a few concrete needs:

materials arriving on time

consistent and predictable movement between stations

fewer human-dependent decisions

the ability to trace what moved, when, and to where

flexibility to adjust routes when a line changes

AGVs fit naturally into this environment because they are essentially “mobile, information-connected transport units” rather than just electric carts.

2. Why Material Handling Became the Weak Link

Most production issues we encounter aren’t caused by robots, CNC machines, or MES systems—they happen in the movement in between.

Manual forklifts and carts introduce uncertainty:

operators sometimes prioritize tasks differently

break time and shift changes slow the line

safety incidents occur in narrow aisles

rapid expansion requires additional labor that may be hard to hire

AGVs simply remove this variability. They don’t replace humans everywhere, but they eliminate the repetitive, high-frequency jobs that constantly interrupt production rhythm.

3. How AGVs Actually Improve Factory Operations

3.1 They keep production moving—even when nothing else does

A single AGV running 24 hours rarely looks impressive. But when you introduce 5–10 vehicles running scheduled jobs, the production line suddenly becomes much more stable. Stations no longer wait for materials “because the forklift is serving someone else.”

3.2 They talk to factory systems instead of waiting for people

Well-built AGV systems integrate with MES or WMS. When a station reports “material low,” the AGV receives a task automatically—no paper orders, no voice calls, no supervisors hunting for operators.

This is where real Industry 4.0 starts to become visible.

3.3 Traffic control is smarter than most people expect

Factories often worry that “multiple AGVs will run into each other.”

Modern fleet management systems prevent this with priority rules, turning control, speed limits, and temporary route changes.

It’s closer to air-traffic control than to a simple robot.

3.4 Safety improves naturally

Every factory that switches from forklifts to AGVs will tell you the same thing:

the workshop becomes noticeably quieter and safer.

Laser scanners, safety buffers, slowdown zones, and obstacle detection make AGVs very predictable, especially in pedestrian-mixed environments.

3.5 Expansion is easier than installing conveyors

One of the real reasons AGVs are replacing traditional conveyors is flexibility.

When a production line changes layout, an AGV route can be adjusted in software instead of removing steel frames, motors, and belts.

4. Why “Conveyors vs. AGVs” Is No Longer a Real Debate

Conveyors make sense for fixed, high-volume lines. But most factories today are adjusting, upgrading, or expanding every year.

AGVs win in scenarios where:

product types change

the factory is still expanding

routes must be modified frequently

installation time must be short

space is limited

Some companies even keep both—conveyors for long straight runs, AGVs for flexible branches and feeding lines.

5. How AGVs Fit Into Industry 4.0 Technologies

AGVs aren’t isolated equipment; they connect to sensors, scheduling systems, and analytics platforms.

IoT: provides status data like battery levels and motor temperature

AI scheduling: reduces waiting time between AGVs

5G networking: allows more vehicles on large sites

Digital twins: simulate congested routes and find better paths

The technology isn’t added “for show”—it solves real bottlenecks you only notice after running AGVs at scale.

6. A Look at Where AGVs Are Being Used Today

AGVs are no longer limited to electronics factories. In the projects we’ve seen, they are working in:

EV battery and automotive plants

metal processing workshops

food and pharmaceutical warehouses

cleanroom environments

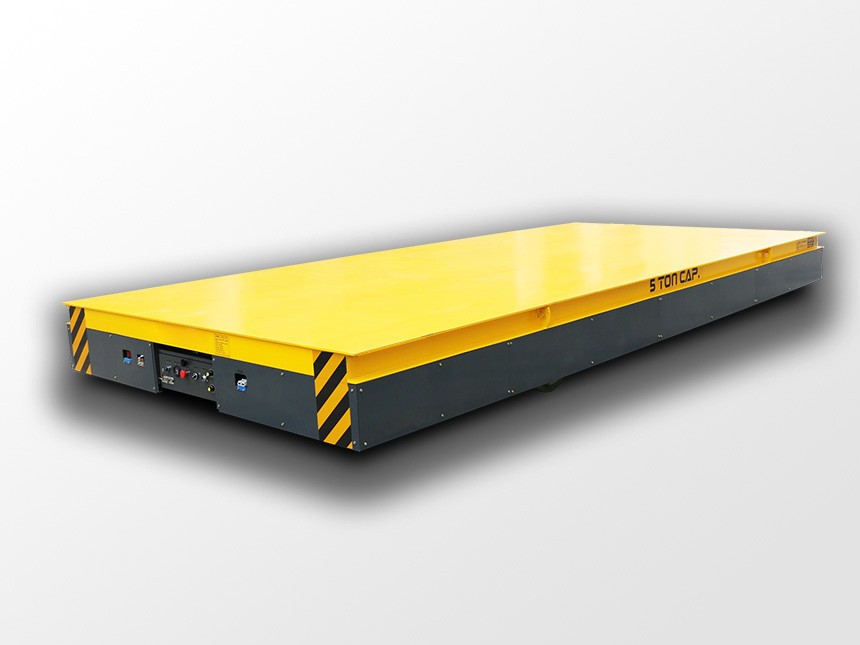

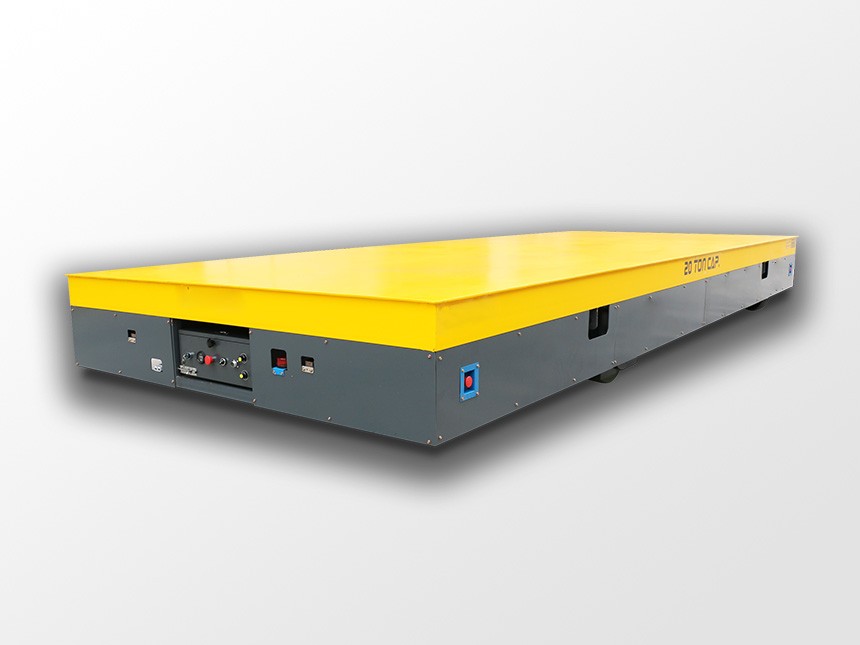

heavy equipment plants handling 30–100-ton loads

The biggest surprise for many factory owners is how quickly AGVs adapt to both small-parts transport and heavy industrial applications.

7. Why Many Clients Choose ATN AGVs

ATN focuses heavily on customized engineering rather than purely standardized catalog products.

Factories often need:

different navigation systems (SLAM, magnetic tape, QR code, hybrid)

heavy-duty structures

integration with existing MES/WMS

non-standard lifting platforms or fixtures

track-based or mixed-navigation systems

This flexibility is exactly why AGVs have become practical for real, complex factories—not just idealized Industry 4.0 showrooms.

Conclusion

Factories don’t adopt AGVs because they are fashionable—they adopt them because material flow affects everything.

When materials move reliably, production becomes predictable, data becomes accurate, and expansion becomes easier.

AGVs are simply the most practical, scalable, and flexible way to achieve that.

As smart factories continue evolving, AGVs are no longer optional—they’re becoming one of the fundamental tools that support the entire manufacturing ecosystem.

English

English 简体中文

简体中文