The battery system inside an Automated Guided Vehicle (AGV) plays a far bigger role than simply supplying power. It directly affects operating hours, maintenance requirements, charging strategy, overall efficiency, and the long-term cost of ownership.

With AGVs now running in 24/7 environments—from cleanrooms to heavy-industry plants—choosing the right battery technology has become a key part of AGV planning.

This article explains the differences between the three most widely used AGV power systems: lead-acid batteries, lithium-ion batteries, and fast-charging technologies. More importantly, it explores how each option fits into different types of workflows.

Why Battery Choice Matters for AGV Performance

Battery selection affects much more than run time. It shapes:

How often an AGV needs to charge

The size of the charging infrastructure

Routing and scheduling strategies

Maintenance routines

Energy efficiency

Total lifetime cost

In other words, the right battery keeps an AGV fleet running smoothly and helps avoid bottlenecks or unnecessary downtime.

Lead-Acid Batteries: The Classic Workhorse

Lead-acid batteries have powered industrial equipment for decades, and many early-generation AGVs were designed around them.

1 What Makes Lead-Acid Batteries Appealing

While less common today in high-performance AGV fleets, lead-acid still has a few clear benefits:

Lower upfront investment

Proven, mature technology

Simple charging equipment

Reliable performance for light workloads

For facilities with limited budgets or low-intensity transport needs, lead-acid can still be a viable option.

2 Practical Limitations to Consider

However, lead-acid batteries come with several drawbacks that impact modern automation:

Long charging times (typically 6–8 hours)

Reduced lifespan if discharged too deeply

Frequent maintenance—water refilling, equalization

Heavy weight, affecting AGV design

Lower energy density

In fast-paced production lines or 24/7 warehouses, these disadvantages often create operational constraints.

3 Best Use Cases

Lead-acid batteries still work well in:

Low-duty cycles

Small plants with minimal AGV usage

Non-critical, short-distance tasks

Environments where downtime is not a major issue

But overall, most modern AGV projects now prefer lithium-ion solutions.

Lithium-Ion Batteries: The Modern Standard for AGVs

Lithium-ion batteries have become the dominant choice for AGVs in recent years—and for good reason.

They offer a strong combination of performance, efficiency, and safety.

1 Key Advantages

Lithium-ion technology provides several benefits that align well with the needs of smart factories:

Fast charging (typically 1–2 hours)

Long cycle life—often 3x–4x longer than lead-acid

High energy density—more power with less weight

Minimal maintenance

Stable performance during heavy workloads

For AGVs operating around the clock, these advantages create a much smoother and more predictable workflow.

2 Safety and Thermal Performance

Modern AGV lithium-ion batteries include:

BMS (Battery Management System)

Temperature monitoring

Overcharge and discharge protection

Cell balancing

Fault alarms

These features help ensure reliability even in demanding conditions such as cleanrooms, refrigerated warehouses, or high-humidity environments.

3 Where Lithium-Ion Excels

Lithium-ion is ideal for:

Multi-shift production environments

Long travel distances

Heavy-duty AGVs

High-accuracy, high-responsiveness tasks

Facilities aiming for fully automated operation

In short—if your workflow requires consistency, lithium-ion is usually the best choice.

Fast-Charging Systems: For High-Frequency, High-Speed AGVs

As AGVs become more integrated into continuous production, many factories are turning to fast-charging or opportunity-charging systems.

These are often powered by:

Supercapacitors

LTO (Lithium Titanium Oxide) batteries

Hybrid energy systems

Unlike conventional batteries, these solutions offer rapid bursts of energy.

1 The Main Appeal: Minimal Downtime

Fast-charging systems allow AGVs to recharge in:

30 seconds

1 minute

3 minutes

During routine stops

This makes them perfect for workflows where the AGV has short waiting periods between tasks.

2 Strengths of Fast-Charging Systems

Extremely long cycle life (tens of thousands of cycles)

Ultra-fast charging

High power output

Ideal for repetitive, tight-cycle tasks

Supports nearly continuous operation

3 Trade-Offs to Know

Lower total energy capacity than lithium batteries

Typically require dedicated charging pads

Best suited for predictable, short-distance paths

If your AGVs move constantly throughout the day with short pauses, fast-charging technology can create significant efficiency improvements.

How to Choose the Right Battery for Your AGV Fleet

Selecting the correct battery type depends on the structure of your workflow—not just cost.

Here’s a simple decision framework:

1 Choose Lead-Acid If:

Budget is extremely limited

The AGV is used a few hours per day

Overnight charging is acceptable

Maintenance is not a concern

2 Choose Lithium-Ion If:

Your factory runs multiple shifts

AGVs must operate for extended hours

You need stable, reliable performance

You want minimal maintenance

Charging downtime must be reduced

3 Choose Fast-Charging Systems If:

AGVs operate almost nonstop

The route includes frequent short stops

High cycle speed is required

You need near-continuous performance

High precision or fast transfers are part of the workflow

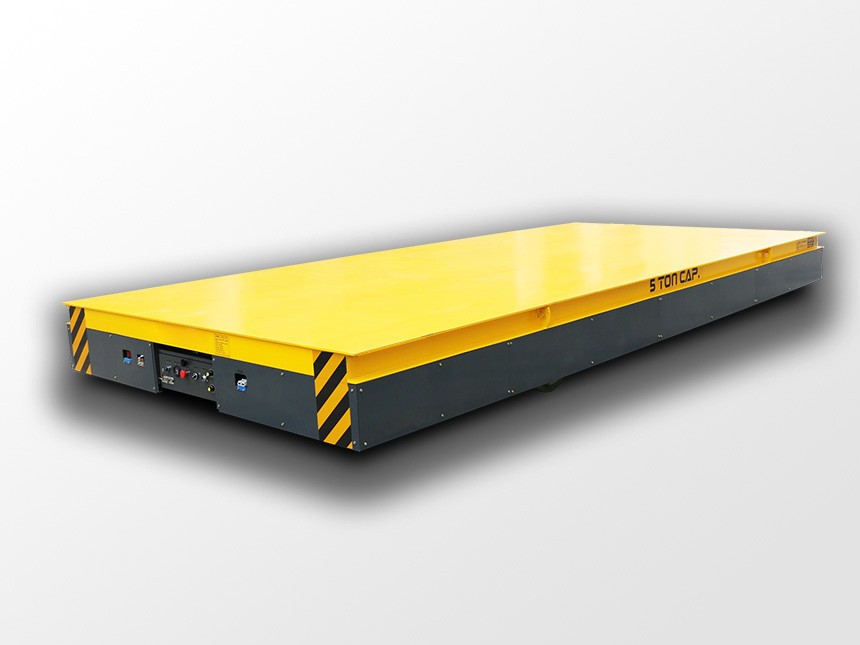

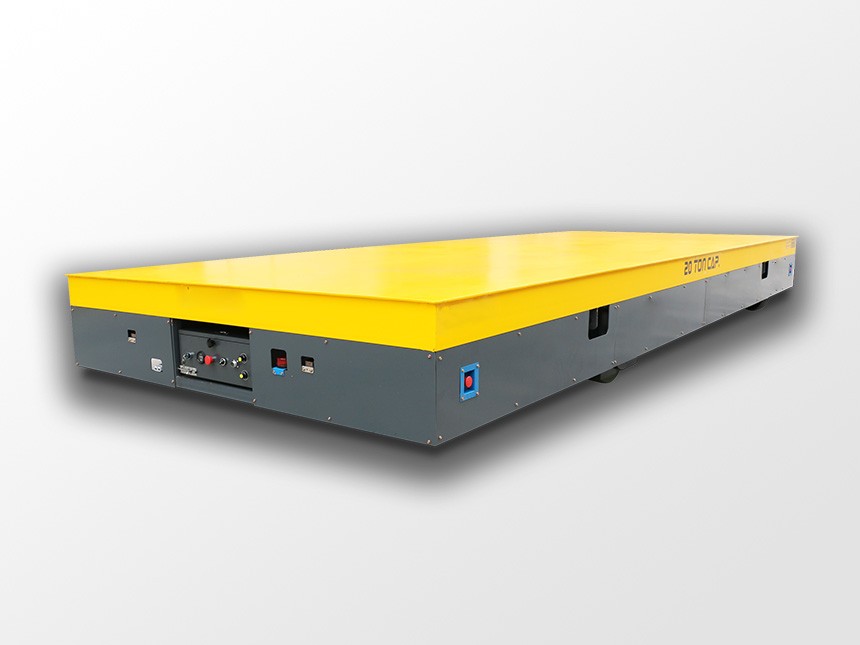

ATN’s Battery Options for Industrial and Heavy-Duty AGVs

ATN provides multiple battery technologies across its AGV lineup, including:

Lead-acid (for budget-focused applications)

Lithium-ion battery systems

Fast-charging industrial systems

Custom energy solutions for special environments

With experience supplying AGVs from 1 ton up to 100+ tons, ATN helps manufacturers choose the power system best suited to:

Load capacity

Duty cycle

Route design

Speed requirements

Environmental conditions

Long-term automation goals

Factories in more than 48 countries currently use ATN’s battery-powered AGVs in automotive, energy, electronics, and heavy-industry environments.

Learn more at: https://www.atnagv.com

Conclusion

Battery technology has a direct impact on AGV performance, operating efficiency, and long-term ROI.

Lead-acid offers affordability, lithium-ion delivers the best all-around capability, and fast-charging systems provide unmatched uptime for demanding workflows.

By understanding the strengths and limitations of each power system, manufacturers can build AGV fleets that operate smoothly, sustainably, and with maximum productivity.

English

English 简体中文

简体中文