A well-designed AGV layout is the backbone of a smooth internal logistics system. Even the best AGVs cannot perform efficiently if the floor routes are narrow, the stations are placed poorly, or the material flow creates unnecessary congestion. Whether you are planning an AGV system for a manufacturing line, a warehouse, or a cleanroom, the design of the layout determines how well your automation will function.

This article explains the key principles behind AGV layout design and offers practical guidance based on real-world deployment experience.

Why AGV Layout Design Matters

The layout of an AGV route directly influences how efficiently materials move, how many AGVs are required, how often vehicles need recharging, and how safely they operate around workers. A thoughtful layout also reduces collisions, prevents route bottlenecks, and supports future expansion. In many facilities, a simple improvement in route direction or station placement can result in significant gains in throughput and cycle time.

Start With a Clear Understanding of Your Workflow

Before mapping any AGV routes on the floor plan, it is essential to understand the existing material flow. This includes identifying what materials need to move, where their journeys begin and end, how frequently they move, and how they interact with production takt time.

The planning stage often involves reviewing existing CAD drawings, observing operators on-site, studying traffic patterns, and mapping out high-frequency material flows. The goal is to determine which processes are most repetitive and time-critical. These high-impact tasks are usually the best candidates for automation.

Designing the Main AGV Route

AGV routes generally fall into one of three structures: loop routes, point-to-point routes, or combined multi-zone networks.

A loop route forms a continuous circular or rectangular path that AGVs follow in one direction. This approach is extremely stable and works well for production environments where materials must circulate in a predictable rhythm, such as in automotive assembly lines or electronics plants.

A point-to-point layout allows AGVs to travel directly between stations based on real-time needs. This design is more flexible and better suited for warehouses or machining workshops where tasks change frequently.

A combined or multi-zone layout divides the facility into zones, each with its own route behavior. This structure is commonly used in large factories where some areas require high precision and others need flexibility. It also provides better scalability when new production lines or equipment are added later.

Designing Aisles, Intersections, and Stations

Aisle width is one of the most important considerations, and it must match the AGV’s size, steering mode, and required safety clearance. Light-duty AGVs can work in relatively narrow corridors, while heavy-duty AGVs often need wide lanes to ensure safe braking and stable load movement.

Sharp turns or tight corners can cause speed reductions and increase wear on the vehicle. Gentle curves create smoother navigation and allow higher throughput. Intersections must be positioned carefully because they are the most common locations for congestion. Ideally, intersections should avoid areas with high pedestrian activity or forklift traffic.

Loading and unloading stations should be placed where AGVs can dock without being blocked by other equipment or workers. Stations need clear visual markers, stable stoppers, and enough approach space to ensure docking accuracy. In cleanrooms or temperature-controlled environments, docking precision is even more important to maintain cleanliness and temperature integrity.

Managing Traffic Flow and Preventing Congestion

Traffic control is essential once multiple AGVs operate in the same area. A layout should avoid narrow choke points and routes that force several AGVs to merge into a single lane. Buffer zones or waiting areas should be built near high-traffic stations so that AGVs can queue without blocking the main pathway.

Modern AGV fleet software helps coordinate traffic by assigning route priorities, scheduling missions intelligently, and ensuring urgent materials reach their destinations without interruption. Although software helps tremendously, a smart physical layout reduces the risk of unnecessary stops and delays.

Planning a Charging Strategy

Charging must be integrated into the layout from the beginning.

Traditional dock charging stations are positioned at the edge of the facility, allowing AGVs to park and charge during longer breaks. This approach is suitable for slow-charging batteries or low-intensity operations.

Opportunity charging or inline charging is common in newer systems. AGVs recharge briefly during loading, unloading, or waiting periods. This approach is ideal for 24/7 operations because it keeps the fleet running continuously without long charging downtime. Short-burst charging pads are often placed near busy routes to maximize convenience.

Layout Considerations for Different Environments

Manufacturing plants often operate with precise takt times, so AGV routes must closely match the timing of each production step. Straight paths help keep movement efficient, and keeping AGV routes separate from forklift areas dramatically increases safety.

Warehousing environments usually require more flexibility, especially if product types or storage zones change frequently. AGV routes in warehouses may include fast express paths for long distances and slower sections near picking areas. Efficient separation between inbound and outbound zones prevents unnecessary cross-traffic.

Cleanrooms require special attention to contamination control. AGVs must travel smoothly with minimal vibration to avoid particle generation. Routes should avoid air shower zones or doorways where pressure changes occur. Anti-static materials and cleanroom-grade wheels are often necessary, and layout planners must ensure that AGVs do not disrupt airflow patterns.

Common Mistakes to Avoid

Several layout errors occur repeatedly in AGV projects. Some planners attempt to impose overly complex route networks that confuse traffic flow. Others place stations too close together, causing AGVs to queue unnecessarily. Tight turns, poorly placed pedestrian crossings, and a lack of maintenance access are also frequent problems.

Another common issue is designing a layout only for current needs and forgetting future expansion. A good AGV layout should support new machines, added production lines, or increased order volumes for years to come.

How ATN Assists With AGV Layout Planning

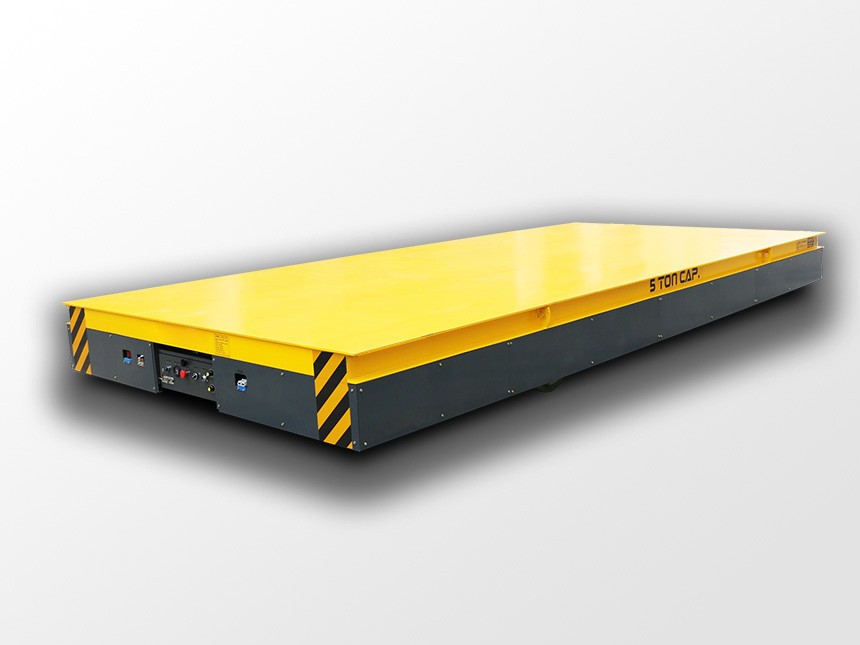

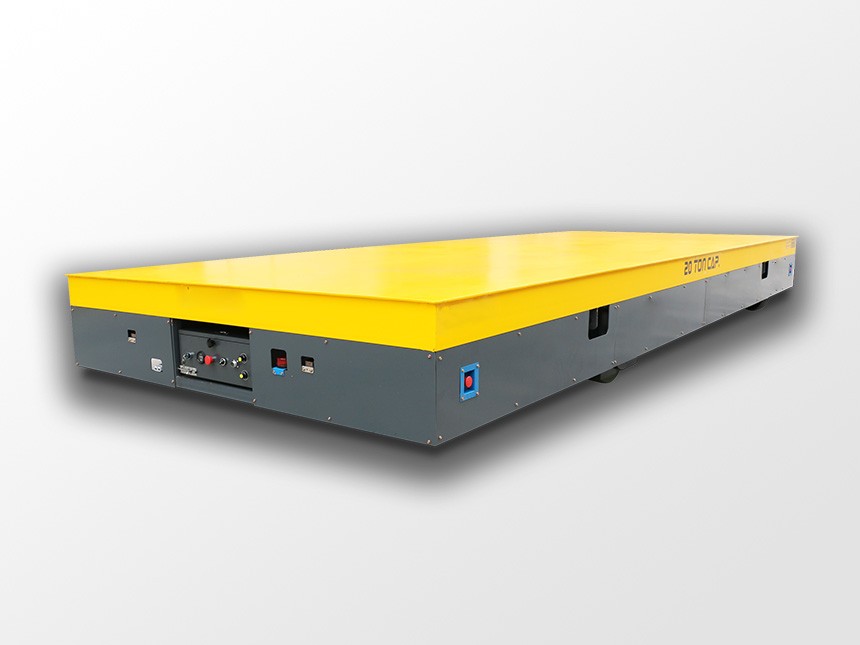

ATN provides a complete layout planning service that includes on-site workflow studies, CAD-based route design, turning simulations for heavy-duty AGVs, and full integration with MES, WMS, or ERP systems. Our engineers review traffic patterns, evaluate material flow frequency, and simulate fleet behavior to ensure stable and efficient operation.

With AGV installations across more than 48 countries, ATN has experience designing layouts for automotive factories, electronics cleanrooms, wind-turbine workshops, metal processing plants, and large warehouse operations.

Conclusion

AGV layout design is far more than drawing lines on a map. A well-planned layout ensures that materials move efficiently, workers operate safely, and the entire system runs smoothly as production grows.

By understanding workflow requirements, choosing appropriate route structures, designing safe aisles, and planning for charging and future expansion, manufacturers can create AGV systems that deliver long-term reliability and real performance improvements.As factories continue moving toward automation and digitalization, a thoughtful AGV layout becomes one of the most critical investments a company can make.

English

English 简体中文

简体中文