For decades, forklifts have been the backbone of material handling in factories and warehouses. They are familiar, flexible, and widely available. But as automation becomes a priority and labor challenges continue to grow, many facilities are now evaluating whether Automated Guided Vehicles (AGVs) can deliver better long-term performance.

This shift is not just about replacing one piece of equipment with another—it reflects a deeper change in how manufacturers think about safety, operational cost, and the value of automation. Understanding the differences between forklifts and AGVs helps businesses make informed decisions about the future of their internal logistics.

Safety: The Most Important Difference

Forklift accidents remain a major concern in industrial environments. Human-operated vehicles are subject to fatigue, distraction, misjudgment, blind spots, and inconsistent driving behavior. Even well-trained operators can make mistakes, especially during busy shifts or in congested areas. These risks can lead to damaged goods, machine downtime, and worker injuries.

AGVs take a fundamentally different approach to safety. Their movements are predictable, controlled, and repeatable. Each AGV is equipped with sensors, scanning lasers, onboard cameras, and emergency stop systems that constantly monitor the environment. If a person or object enters its path, the AGV slows down or stops immediately. Because AGVs follow predefined routes and operate at controlled speeds, the environment becomes far more stable and less chaotic.

For factories that prioritize accident reduction and safety compliance, AGVs offer a clear advantage.

Cost: Upfront Price vs Long-Term ROI

At first glance, forklifts appear cheaper because the purchase price is relatively low. However, the ongoing costs associated with labor, training, fuel or battery replacements, certification, and safety incidents can add up quickly. Manual forklifts also require operators for every shift, which means higher recurring labor expenses.

AGVs typically cost more upfront, but the long-term financial picture looks different. Once deployed, AGVs do not require drivers, overtime pay, breaks, or shift rotations. Maintenance is more predictable, and energy consumption is lower. Most companies begin to see a significant return on investment within two to four years, especially in multi-shift operations.

Factories facing rising labor costs, worker shortages, or high turnover often find that AGVs provide better financial stability over time.

Productivity and Consistency in Daily Operation

Forklifts offer flexibility because a trained operator can move in any direction and handle sudden task changes. However, productivity can vary depending on the driver’s experience, workload, and fatigue. Human-driven vehicles also tend to cause workflow interruptions—such as waiting for a forklift to arrive or rearranging equipment to give it space.

AGVs excel at consistency. They follow precise schedules, repeat movements flawlessly, and maintain steady cycle times throughout the day. With fleet-control software, multiple AGVs coordinate automatically, choosing the most efficient routes and avoiding traffic conflicts. This automation eliminates delays caused by human availability or fluctuations in operator performance.

When material flow needs to be reliable and predictable, AGVs deliver a level of consistency that forklifts simply cannot match.

Scalability and Automation Strategy

Forklifts work best in environments where flexibility is critical and material flow changes frequently. But as production volumes rise or new product lines are added, coordinating forklift traffic becomes more difficult. More forklifts mean more operators, more training, and increased complexity.

AGV systems scale smoothly. Adding another AGV does not require a new operator—only software integration and route configuration. The system automatically calculates how an additional vehicle affects traffic flow. As factories move toward Industry 4.0, AGVs fit naturally into automated processes, linking directly to MES, WMS, and ERP systems for real-time material tracking and intelligent scheduling.

AGVs support long-term digital transformation, whereas forklifts often remain isolated manual tools.

Environmental Impact and Energy Efficiency

Traditional forklifts, especially fuel-powered models, generate emissions and noise that can disrupt workers and affect indoor air quality. Even electric forklifts have higher energy consumption due to their design and heavy lifting mechanisms.

AGVs typically use more efficient lithium-ion or fast-charging battery systems. Their energy consumption is lower because their movements are optimized by software and they operate at controlled speeds. The reduction of unnecessary idling, rapid acceleration, or sudden braking further improves efficiency and reduces wear on components.

For companies aiming for greener operations or pursuing sustainability certifications, AGVs contribute positively to environmental goals.

Maintenance and Equipment Lifespan

Forklifts require regular inspections, tire replacements, brake adjustments, and hydraulic maintenance. Wear and tear vary depending on operator behavior—some drivers may be gentle, while others may cause increased mechanical stress.

AGVs, on the other hand, benefit from consistent operation patterns. Their acceleration, braking, and turning are all software-controlled, which reduces unnecessary mechanical strain. Many AGV systems include built-in diagnostics that notify maintenance teams before issues become serious. This predictive approach extends the vehicle’s lifespan and reduces downtime.

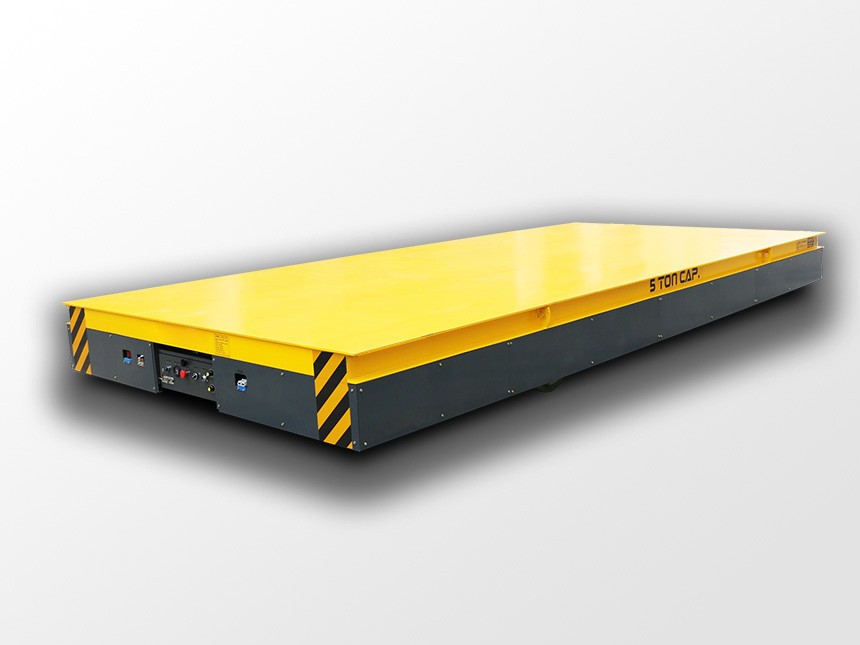

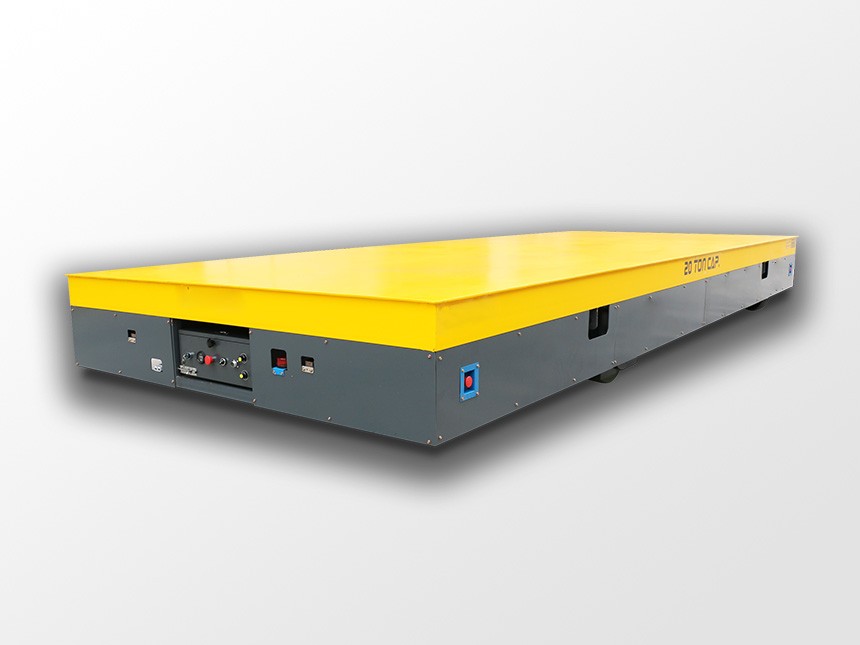

Heavy-duty AGVs, especially those designed by specialized manufacturers such as ATN, are engineered for long-term durability in industrial environments.

Choosing Between Forklifts and AGVs

The decision is not always an either-or situation. Some facilities use both forklifts and AGVs to maximize flexibility and efficiency. Forklifts may still handle heavy lifting, outdoor transport, or irregular tasks that require human judgment. AGVs excel in repetitive, routine movements that demand consistency and long-term reliability.

A simple way to decide is by evaluating how structured or predictable your material flow is. Workflows that repeat hundreds of times per day are ideal candidates for AGV automation. Environments that change frequently or require complex maneuvering may still benefit from forklift operation.

In many modern factories, the best results come from a hybrid system where AGVs handle steady internal logistics while forklifts focus on dynamic tasks.

ATN’s AGV Solutions for Modern Industrial Facilities

ATN provides a complete range of AGVs designed to replace or complement forklift operations. Our portfolio includes standard AGVs, heavy-duty transport AGVs ranging from 10 to over 100 tons, cleanroom AGVs, and customized solutions tailored to specific production requirements.

With more than a decade of experience and deployments in over 48 countries, ATN helps manufacturers transition from manual forklift logistics to intelligent, automated material handling systems that enhance safety, productivity, and long-term operational efficiency.

More information: https://www.atnagv.com

Conclusion

Forklifts and AGVs each offer unique advantages, but AGVs are rapidly becoming the preferred choice for factories seeking higher safety, lower operating costs, and fully automated workflows. Forklifts remain valuable for irregular tasks, but AGVs dominate when consistency, predictability, and scalability matter most.

As factories continue moving toward automation and digitalization, AGVs are laying the foundation for safer, smarter, and more efficient logistics systems.

English

English 简体中文

简体中文