Lean manufacturing focuses on eliminating anything that does not create value for the customer. Whether it is unnecessary motion, excessive inventory, transportation delays, or inconsistent workflows, every form of waste ultimately increases cost and slows production. As factories move toward smarter and more efficient operations, Automated Guided Vehicles (AGVs) have become one of the most reliable tools for supporting lean principles.

Unlike traditional material handling methods, AGVs offer predictable, repeatable, and highly optimized movement of goods. This stability helps factories achieve the core goals of lean manufacturing—higher efficiency, lower waste, and greater value.

Creating a More Stable and Predictable Material Flow

One of the foundations of lean manufacturing is establishing a smooth, continuous flow of materials. Manual handling often disrupts this flow because forklifts may arrive late, take an inefficient path, or struggle with operator fatigue during peak hours. These disruptions create bottlenecks that slow down downstream processes.

AGVs, by contrast, operate on fixed routes and follow schedules with precise timing. Their movements are controlled by software, allowing them to deliver materials exactly when needed. This consistency eliminates waiting time between processes and ensures that each workstation receives the correct part or component at the right moment. A smoother flow reduces downtime, prevents line stoppages, and maintains the stable production rhythm that lean manufacturing requires.

Reducing Motion and Transportation Waste

Excessive movement—whether of people, materials, or equipment—is one of the most common sources of waste in industrial environments. Forklift operators may take longer routes, carry partially filled loads, or travel empty to return to a starting point. These inefficiencies accumulate over time and translate into higher labor and energy costs.

AGVs significantly reduce this form of waste because their routes are optimized through intelligent scheduling systems. Each trip is purposeful, and the vehicle does not travel unless there is a defined task. AGVs also eliminate unnecessary human travel, allowing workers to stay focused on value-added activities instead of moving materials from one area to another. Over time, this shift in responsibility dramatically improves labor productivity.

Supporting Just-in-Time Delivery

Just-in-time (JIT) production is a key pillar of lean manufacturing. It requires delivering parts only when needed, in the quantity needed, and without overstocking. Manual transport systems often force factories to compensate for irregular arrival times by building larger buffer inventories, which increases cost and consumes valuable space.

AGV systems make JIT delivery far easier to implement. Because AGVs operate with consistent timing and can run continuously across multiple shifts, material replenishment becomes predictable. This reliability allows manufacturers to reduce safety stock levels and operate with much smaller inventories. Lower inventory means less waste, less storage, and faster response when product specifications change.

Minimizing Defects Through Consistency

Product defects often originate from unstable material handling processes. Rough forklift movements, sudden braking, or unbalanced loads can damage components long before they reach the production line. Lean manufacturing seeks to prevent defects at the source, and AGVs contribute by offering controlled, gentle, and stable transportation.

Because AGVs follow predefined acceleration and braking patterns, the risk of dropping or damaging materials is greatly reduced. This is especially valuable in industries handling fragile items, precision electronics, or high-value components. Reducing damage not only cuts rework and scrap costs but also creates a more reliable upstream supply for the assembly process.

Enhancing Workplace Safety to Support Lean Culture

Lean manufacturing emphasizes building a safe and organized workplace where processes run smoothly without interruption. Forklift accidents, near misses, and congestion are all disruptions that affect production stability and create hidden waste in the form of delays, investigations, and downtime.

AGVs significantly improve safety by eliminating unpredictable human driving behavior. Their built-in sensors, controlled speeds, and collision avoidance functions help maintain a calm and orderly work environment. A safer environment reduces accidents, minimizes chaos, and strengthens the consistency required for lean culture to thrive.

Improving Space Utilization

Efficient use of space is another important aspect of lean thinking. Forklifts typically require wide aisles to accommodate turning radius and operator visibility. This forces factories to allocate more floor area to movement rather than value-adding activities.

AGVs can operate in much narrower aisles because they follow exact digital routes and do not rely on broad turning areas. In warehouses or production facilities, this often frees up a considerable amount of space that can be used for additional equipment, storage, or new production lines. Better space utilization supports higher operational efficiency and simplifies future expansion.

Enabling Standardized and Error-Free Processes

Lean manufacturing depends on standardization to eliminate variation and ensure quality. Manual material transport naturally introduces variations in timing, speed, route selection, and delivery accuracy. These inconsistencies require constant coordination and corrective action.

AGVs bring an entirely different level of standardization. Each trip, docking action, and station stop follows a fixed digital script. Deliveries occur in the same way every time, which stabilizes upstream processes and helps operators focus on their tasks without worrying about material arrival. The result is a production environment with fewer disruptions and greater repeatability.

Building a Foundation for Long-Term Automation

Lean manufacturing does not only focus on eliminating waste today—it aims to build systems that remain efficient in the future. AGVs provide flexibility and scalability that allow factories to grow without major layout changes or large investments in new infrastructure.

As production increases, new AGVs can be added to the fleet with minimal effort. Routes can be updated digitally without rebuilding conveyor lines or modifying the workshop structure. This adaptability ensures that lean improvements can continue even as business needs evolve.

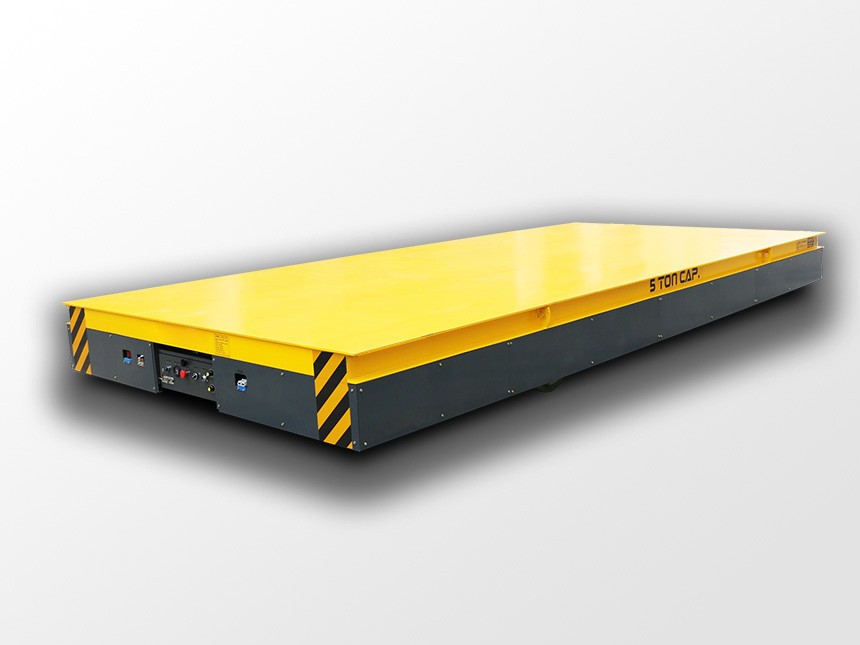

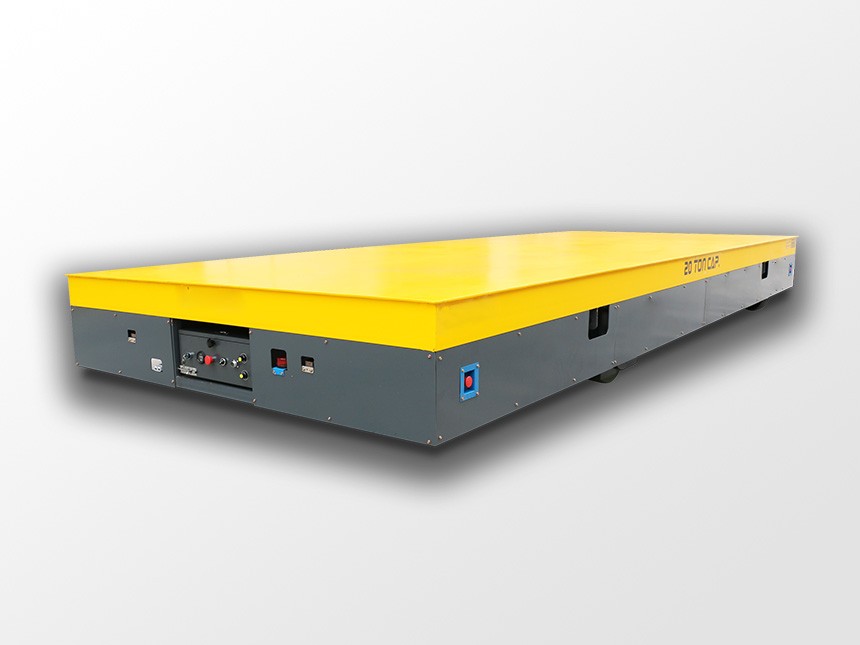

ATN AGV Solutions Designed for Lean Environments

ATN provides a full range of AGV solutions that support lean transformation across manufacturing, warehousing, and cleanroom environments. Our vehicles are engineered for efficiency, stability, and continuous operation. Whether transporting small components or handling heavy loads of more than 100 tons, ATN AGVs deliver the precision needed to sustain lean workflows.

With deployments in over 48 countries and deep experience in lean-focused industries such as automotive, electronics, and advanced manufacturing, ATN supports companies at every stage of their automation journey.

Learn more at: https://www.atnagv.com

Conclusion

AGVs play a powerful role in supporting lean manufacturing. By stabilizing material flow, reducing waste, lowering inventory, and improving workplace safety, AGVs help factories operate more efficiently and more profitably. Their consistency and scalability make them an ideal technology for companies pursuing long-term lean transformation.

As global manufacturing becomes increasingly competitive, AGVs provide the stability and precision needed to achieve truly lean operations.

English

English 简体中文

简体中文