Navigation technology is one of the most important elements in any AGV system. It determines how accurately the vehicle moves, how easily it adapts to layout changes, and how well it handles complex environments. With so many navigation options available today—laser, vision, magnetic tape, QR code, inertial guidance, and hybrid systems—choosing the right one can feel overwhelming.

Finding the best navigation method requires understanding your facility’s layout, project goals, environmental conditions, and long-term automation strategy. This article explains how each navigation system works and how to make an informed decision based on real-world needs.

Why Navigation Technology Matters

The navigation system is the AGV’s “eyes” and “brain.” It tells the vehicle where it is, where it needs to go, and how to move safely along the way. Good navigation ensures accuracy, smooth traffic flow, and predictable performance. Poor navigation, on the other hand, can cause route drift, unexpected stops, frequent recalibration, or even collisions.

Because AGV systems often operate 24/7, the wrong navigation choice can create ongoing inefficiencies. A suitable navigation method improves reliability, lowers maintenance requirements, and ensures the AGV performs consistently across different shifts.

Laser Navigation: Precision for Dynamic Environments

Laser navigation has become one of the most widely adopted solutions in modern AGVs. By rotating a laser scanner to detect reflectors installed around the facility, the AGV calculates its exact position in real time. This approach offers high accuracy and allows the vehicle to adapt to changes in the environment, such as new machines or temporary obstacles.

Factories that operate in fast-changing layouts or require high positional accuracy often choose laser navigation. It is especially suitable for electronics assembly, automotive production, and multi-line manufacturing centers where flexibility is crucial. The main consideration is the need to install reflectors throughout the facility, but once installed, the system provides exceptional stability.

Vision Navigation: Ideal for Facilities Prioritizing Flexibility

Vision navigation uses onboard cameras and AI algorithms to read its surroundings and navigate through them. Instead of reflectors or physical markers, the AGV relies on visual features such as corners, textures, or ceiling patterns. This makes the system highly adaptable and allows it to work in areas where installing reflectors or magnetic paths is impractical.

Vision-based systems are a strong choice for warehouses or cleanrooms where the environment is visually consistent. Because they rely heavily on image data, lighting conditions must remain stable. When used in controlled facility environments, vision navigation can reduce infrastructure modification and enable easy route updates through software.

Magnetic Tape Navigation: A Practical and Cost-Effective Option

Many factories still rely on magnetic tape navigation because it is simple, stable, and budget-friendly. The AGV follows magnetic strips placed on the floor, which means installation is quick and does not require advanced sensors. This method works well for highly repetitive workflows where routes rarely change and precision requirements are moderate.

However, magnetic tape has limitations. Physical wear, heavy forklift traffic, or accidental peeling can affect performance. The method also requires layout changes to be done manually by replacing the tape. Despite these drawbacks, magnetic navigation remains an effective solution for facilities seeking low-cost automation with predictable routes.

QR Code and Marker Navigation: Controlled Accuracy with Low Infrastructure Cost

QR-code or landmark navigation systems use printed markers placed on the floor or ceiling. When the AGV reads a marker, it updates its position and continues navigating along a predefined map. This method is more flexible than magnetic tape and requires fewer environmental changes than laser navigation.

QR navigation is popular in manufacturing environments with clear linear processes or in warehouses with stable aisle structures. It is also a good choice for factories that want digital navigation but do not require the full accuracy of laser systems.

Inertial Navigation: Best for Heavy Loads and Harsh Conditions

Inertial navigation relies on onboard gyroscopes, accelerometers, and reference magnets. It performs extremely well in environments where dust, temperature, vibration, or electromagnetic interference make other navigation methods unstable.

Because inertial systems do not rely on visual cues or reflective markers, they are ideal for heavy-duty AGVs or material carriers operating in sectors such as metal processing, machining workshops, steel plants, or battery manufacturing. While the initial setup may be more specialized, the long-term reliability in harsh environments makes it a valuable option.

Hybrid Navigation: Combining Strengths for Complex Scenarios

Many modern AGVs use hybrid navigation systems that blend laser, vision, inertial, or QR navigation. This allows the AGV to switch seamlessly between methods depending on the environment. For example, the AGV may use laser navigation in open spaces, vision navigation in narrow corridors, and marker-based positioning near docking stations.

Hybrid systems offer the highest stability, especially in large facilities where conditions vary across different zones. They are commonly used in automotive plants, high-tech factories, and multi-process manufacturing centers where precision and flexibility must coexist.

How to Select the Right Navigation Method

The best navigation system depends on several factors, including your facility’s size, layout complexity, cleanliness requirements, frequency of layout changes, budget, and the accuracy needed for docking or lifting tasks. Factories with rapidly changing layouts often prefer laser or vision navigation. Facilities with predictable workflows may choose magnetic or marker-based systems. Heavy-duty industries typically rely on inertial or hybrid solutions.

The selection process always begins with a technical assessment. This includes evaluating floor conditions, identifying obstacles, reviewing lighting and visibility, and analyzing how materials move across shifts. A well-chosen navigation system ensures safe, efficient, and reliable operation for years.

ATN’s Expertise in Navigation Integration

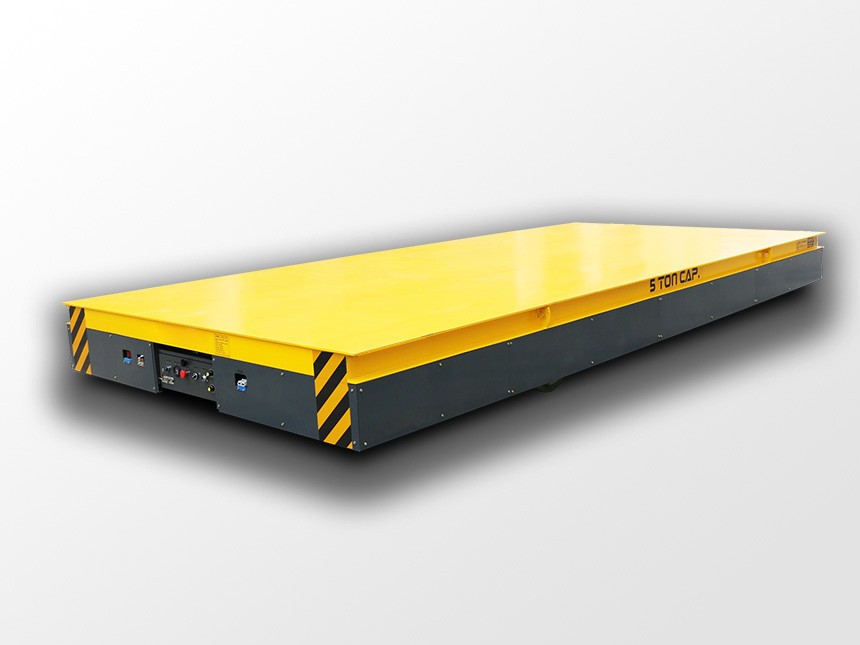

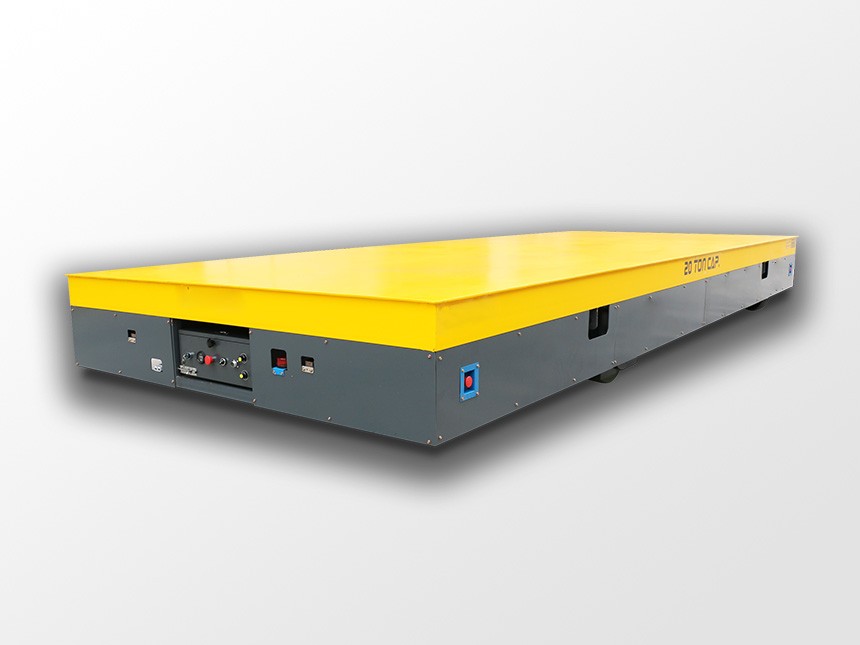

ATN offers a full range of AGV navigation systems, including laser SLAM, vision-based navigation, magnetic tape, QR-code positioning, inertial guidance, and hybrid multi-sensor solutions. Our team evaluates environmental conditions, traffic patterns, and production goals to ensure the navigation system matches your operational needs.

With AGV deployments in more than 48 countries, ATN has experience designing navigation strategies for electronics factories, heavy equipment workshops, cleanrooms, metal-processing plants, and large warehousing systems.

More information is available at: https://www.atnagv.com

Conclusion

Choosing the right navigation system is one of the most important decisions when planning an AGV project. Each method—whether laser, vision, magnetic, or hybrid—offers its own advantages depending on the factory’s layout and operational priorities. A well-selected navigation system ensures smooth movement, consistent accuracy, and reliable performance across all shifts.

As automation continues to advance, navigation technology will remain the foundation of AGV success. With the right system in place, factories can achieve higher efficiency, safer workflows, and long-term adaptability.

English

English 简体中文

简体中文