Modern factories are no longer isolated production units. They are data-driven ecosystems where machines, software, and people work together in real time. Automated Guided Vehicles (AGVs) have become a central part of this transformation, taking over repetitive transportation tasks and linking different stages of production. Yet, the true value of an AGV system only becomes visible when it is integrated with higher-level management platforms such as MES, WMS, and ERP.

Integration turns AGVs from simple transport machines into intelligent components of a digital manufacturing system. This article explains how AGVs connect with these platforms, why the integration matters, and what companies should consider when planning such a project.

Why Integration Is the Key to AGV Success

An AGV operating independently can move materials on schedule, but it does not have access to information beyond its predefined tasks. Without integration, AGVs must rely on manual triggers, simple call buttons, or fixed loops. This limits their adaptability and prevents real-time decision-making.

When AGVs are connected to MES, WMS, or ERP platforms, they gain access to a continuous stream of production and inventory information. This allows the vehicles to react instantly to supply gaps, production priorities, or warehouse changes. The result is a smoother, more coordinated operation where material movement is directly linked to business workflows.

Integrating AGVs With MES for Real-Time Production Control

The Manufacturing Execution System (MES) sits at the heart of modern production environments. It monitors scheduling, production progress, workstation status, and process timing. Integrating AGVs with MES allows the transport system to become a natural extension of the production line.

When a workstation finishes a batch, MES can automatically send a command to dispatch an AGV for pickup. If a line is running ahead or falling behind schedule, MES adjusts transportation tasks to match real-time needs. This eliminates waiting times and ensures that every station receives materials precisely when required.

In complex manufacturing environments, this integration helps maintain takt time and prevents sudden slowdowns caused by delayed material delivery.

Connecting AGVs to WMS for Smart Warehouse Operations

The Warehouse Management System (WMS) governs inventory storage, picking, replenishment, and order fulfillment. When AGVs are integrated with WMS, inventory movement becomes more accurate and far less dependent on manual labor.

For example, when a shelf becomes low on stock, WMS can automatically request an AGV to move replenishment materials. When an order is ready for packing, WMS triggers a transport task to deliver the necessary items. Each movement is recorded digitally, allowing warehouse operators to track inventory in real time.

This level of automation reduces errors caused by manual handling and ensures higher inventory accuracy. It also increases throughput in busy warehousing environments where speed and consistency are essential.

Linking AGVs to ERP for Unified Business Management

ERP systems provide a complete view of a company’s operations, from purchasing and production to finance and sales. When AGVs integrate with ERP, logistics operations become visible at the highest business level. This creates a seamless flow of information between material movement and corporate decision-making.

For example, when ERP registers a new production order, AGVs can begin preparing raw materials for the line. When finished goods are ready for shipment, ERP can trigger AGVs to deliver them to outbound areas. This integration ensures that transportation activities are aligned with overall business goals and customer deadlines. It also helps companies adopt more precise planning and forecasting strategies.

How AGVs Communicate With These Systems

AGV integration is made possible through standardized communication protocols such as RESTful APIs, MQTT, OPC UA, and direct database interactions. The AGV fleet management software acts as a central hub, receiving mission requests, assigning tasks to the right vehicle, and updating task status in real time.

In practical terms, this means the AGV system constantly exchanges information such as location, battery level, route status, mission completion, and traffic conditions. Higher-level platforms use this data to plan production more accurately, distribute workload more evenly, and avoid bottlenecks caused by unexpected delays.

Planning a Successful Integration Project

A successful integration begins with understanding the existing digital architecture. Manufacturers must identify which systems hold critical data and how that information should flow to AGVs. The next step is mapping material movement, analyzing process timing, and determining which tasks should be automated.

During implementation, each interface must be tested carefully to ensure commands are delivered correctly and that AGVs interpret them reliably. Simulation tools are often used to test different scenarios before going live. Once deployed, integration allows AGVs to operate dynamically rather than following static routes or fixed schedules.

Benefits Realized After Full Integration

When AGVs are fully integrated with MES, WMS, and ERP systems, factories gain a higher level of automation and visibility. Material flow becomes smoother, inventory tracking becomes more accurate, and production planning becomes easier to manage. Operators spend less time coordinating transport tasks and more time focusing on quality and process optimization.

The facility becomes less dependent on manual communication, reducing the risk of delays caused by human error or shift handovers. Over time, this integrated ecosystem creates a more stable and responsive operation that aligns closely with Industry 4.0 goals.

ATN’s Integration Capabilities

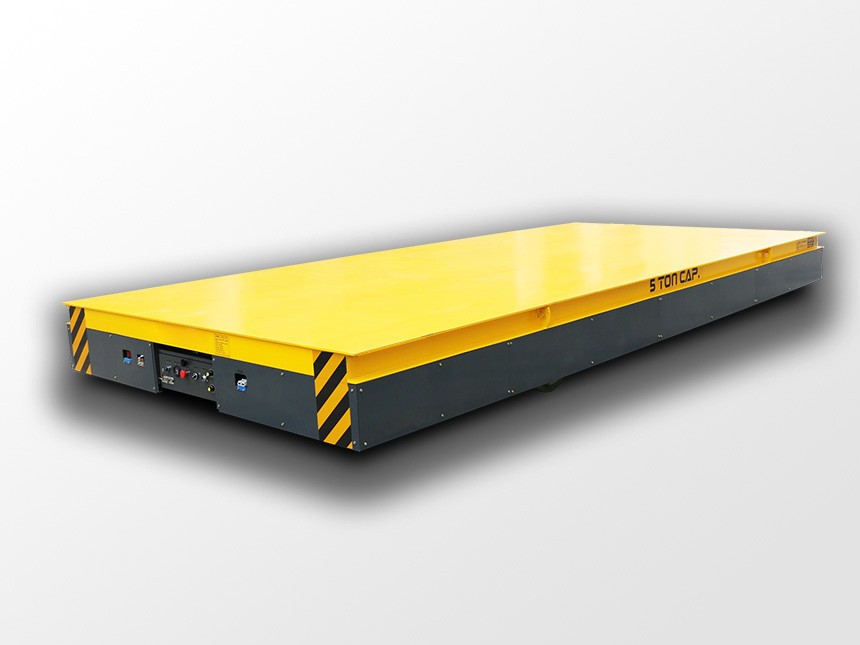

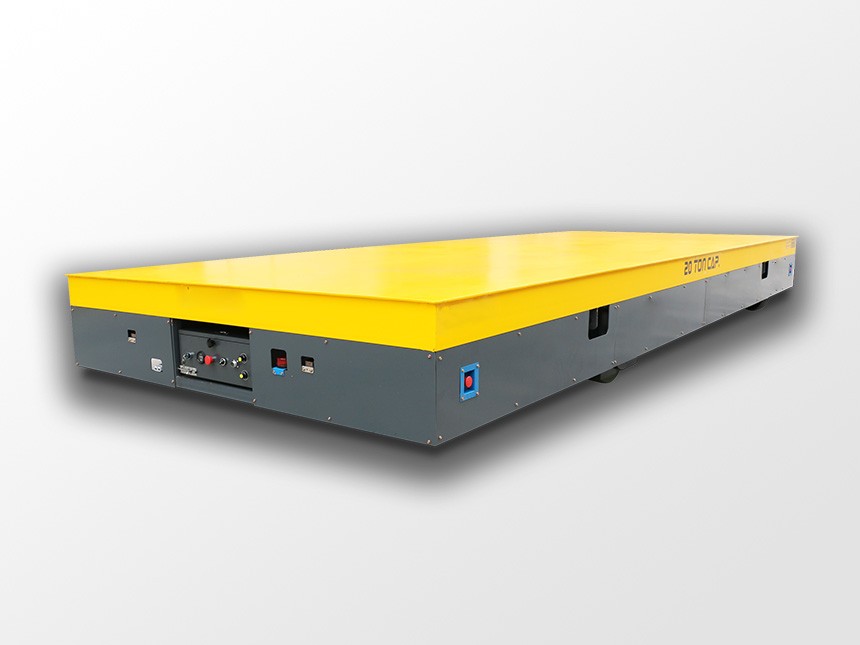

ATN offers integration services that connect AGVs with MES, WMS, ERP, and custom factory systems. Our engineers work closely with customers to evaluate workflow requirements, design API connections, and ensure real-time communication between platforms.

With experience across electronics manufacturing, automotive production, heavy equipment logistics, and warehouse automation, ATN provides reliable AGV solutions that fit seamlessly into existing digital infrastructures.

Learn more at: https://www.atnagv.com

Conclusion

Integrating AGVs with MES, WMS, and ERP systems transforms material handling from a basic transport function into an intelligent, fully coordinated part of factory automation. This connection enables real-time adjustments, creates higher production stability, and lays the groundwork for advanced Industry 4.0 operations.

As more manufacturers pursue digital transformation, AGV integration is becoming a strategic advantage—one that enhances efficiency, reduces waste, and ensures long-term competitiveness.

English

English 简体中文

简体中文