The battery is one of the most critical components in any Automated Guided Vehicle. It determines how long the AGV can run, how quickly it recovers between tasks, and how well it performs during continuous operation. As automation continues to evolve, manufacturers now have several power options to choose from, including lithium-ion batteries, traditional lead-acid batteries, and emerging supercapacitor systems. Each option brings its own advantages and limitations, and selecting the right one requires understanding your facility’s operating rhythm, charging strategy, and long-term goals.

Why Battery Selection Matters for AGV Performance

AGVs rely on stable, predictable power to support navigation, control systems, sensors, and payload movement. An underperforming battery can cause frequent downtime, inconsistent speeds, or unexpected shutdowns that disrupt production. The right battery ensures that the AGV fleet operates smoothly across multiple shifts and can handle the transport workload without interruption. Choosing the right power solution helps avoid bottlenecks and guarantees long-term reliability.

Lithium-Ion Batteries: High Efficiency and Quick Charging

Lithium-ion batteries have become the most popular choice in modern AGV systems. Their energy density is significantly higher than lead-acid, which means the battery can store more power without increasing size or weight. This allows AGVs to run longer between charges and operate with fewer interruptions.

One of the biggest advantages of lithium-ion technology is the ability to support opportunity charging. AGVs can recharge for a few minutes while loading, unloading, or waiting for tasks, allowing them to work continuously across multiple shifts without ever fully stopping for long charging cycles. The lifecycle of lithium-ion batteries is also much longer, often lasting several years even under heavy use.

Although the initial cost is higher, the long-term stability, reduced maintenance, and overall energy efficiency make lithium-ion the preferred option for most modern facilities.

Lead-Acid Batteries: A Budget-Friendly but Less Flexible Choice

Lead-acid batteries are the traditional power source for industrial equipment and remain a cost-effective option for AGV systems. Their main appeal lies in the relatively low purchase price and proven reliability in environments where cost sensitivity is high.

However, lead-acid batteries require longer charging times and often need scheduled battery swaps to support multi-shift operations. They also degrade faster if the battery is not fully charged or discharged properly. These limitations make them less suitable for 24/7 production environments where continuous performance is required.

Despite their drawbacks, lead-acid batteries may still be appropriate for AGVs that operate on simple routes with lower daily usage or in facilities that do not require strict timing.

Supercapacitors: Ultra-Fast Charging for High-Frequency Tasks

Supercapacitors represent a newer approach to AGV power. Instead of storing energy through chemical reactions, they store it physically, which allows extremely fast charging and discharging. In many cases, an AGV powered by supercapacitors can fully recharge in seconds rather than hours.

This makes supercapacitors ideal for high-frequency transport tasks where the AGV has access to charging pads during every cycle. They provide outstanding durability, often exceeding hundreds of thousands of charge cycles without noticeable degradation.

However, supercapacitors store less energy compared to batteries, so they are not suitable for long-distance travel or long shifts without opportunity charging. Their use is most successful in tightly controlled environments where AGVs repeat short, precise movements.

Choosing the Right Battery for Your AGV Application

Selecting the best battery type depends on the operational characteristics of your facility. Lithium-ion batteries are suitable for most modern production lines because they support continuous operation, fast charging, and long-term stability. Lead-acid batteries may be sufficient for simpler applications where AGVs run only a few hours per day or where investment budgets are limited. Supercapacitors excel in specialized environments where charging opportunities exist at frequent intervals and speed is more important than total capacity.

Evaluating your AGV’s duty cycle is the key to making the right choice. Factors such as route length, load weight, shift length, and the availability of charging time play a significant role in determining which power technology will perform best.

The Future of AGV Battery Technology

Battery technology continues to evolve rapidly. Improvements in lithium-ion chemistry, such as LFP and NMC variants, are increasing safety and energy density. Meanwhile, hybrid systems that combine batteries with supercapacitors are emerging to support both long endurance and fast charging. Solid-state batteries may eventually offer even higher performance and safety for AGVs operating in critical environments.

As Industry 4.0 advances, energy management will become even more important. AGVs will increasingly rely on intelligent charging systems that schedule charging cycles automatically based on real-time traffic, task priorities, and energy consumption patterns.

ATN’s Expertise in AGV Power Solutions

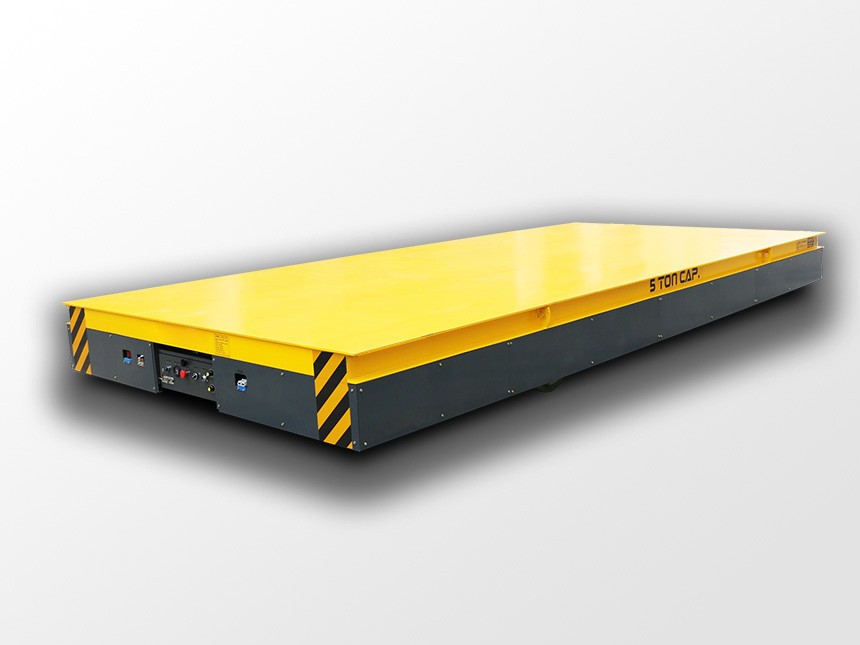

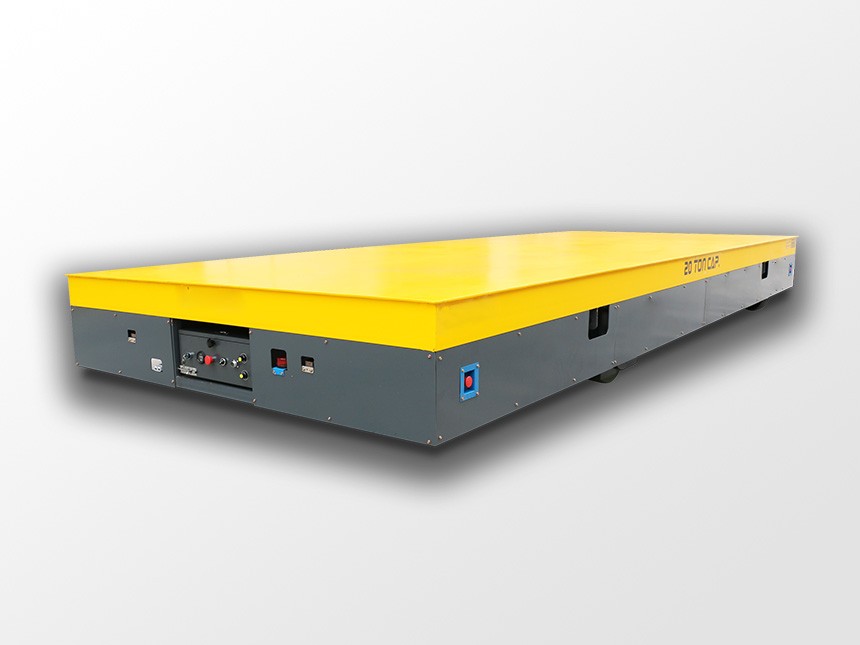

ATN provides AGV systems equipped with a range of battery technologies tailored to different industrial environments. Our lithium-ion and LFP solutions support long-duration operation and fast opportunity charging, while our lead-acid and supercapacitor designs meet the needs of factories with specific cost or cycle requirements.

With installations in more than 48 countries and deep experience in heavy-duty, cleanroom, and multi-shift AGV applications, ATN helps customers choose the most appropriate power system for their long-term automation strategy.

More information is available at: https://www.atnagv.com

Conclusion

Battery selection is one of the most important decisions in any AGV project. Each technology—lithium-ion, lead-acid, and supercapacitor—offers unique advantages depending on the demands of the facility. By understanding the strengths and limitations of each option, manufacturers can choose the most efficient and cost-effective solution for their operational needs.

As AGV usage continues to grow, the right battery system will play a central role in ensuring reliable, round-the-clock performance and long-term return on investment.

English

English 简体中文

简体中文