As AGVs become more common in manufacturing plants and warehouses, workstation and docking-point design has become a key factor that determines how efficiently the entire system runs. A well-built AGV workstation ensures smooth docking, consistent positioning, and fast material handoff. Poorly designed stations, on the other hand, lead to delays, misalignment, and repetitive manual intervention—all of which slow down the automation process.

Designing AGV docking points is not just about creating a place where the vehicle stops. It involves understanding how materials flow through the facility, how operators interact with the system, and how AGVs behave under different conditions. This article explores the essential principles behind building AGV docking points that deliver accuracy, speed, and reliability.

Understanding the Role of Docking Points in AGV Operations

The docking point is where the AGV transitions from movement to interaction. It could be a loading station, an unloading point, a lift-transfer interface, or a position where materials are exchanged with a workstation. If docking is slow or inaccurate, the entire material workflow is affected. Precise alignment is critical because many AGVs must match up with conveyors, lifters, rollers, robotic arms, or fixed storage racks. When docking is repeatable and stable, AGVs can complete tasks with minimal delay and maintain a consistent production rhythm.

The Importance of Clear and Predictable Approaches

Every docking action begins with the AGV’s approach. A smooth, predictable approach ensures that the AGV does not need to make unnecessary corrections as it nears the station. Long, straight approach paths tend to produce the best results because they allow the AGV to perform fine adjustments gradually. When possible, workstations should be positioned to avoid sharp turns or obstructed pathways that force the AGV to slow down or reposition multiple times. A predictable approach reduces cycle time and increases long-term system stability.

Ensuring Enough Space for Alignment and Correction

Even with advanced navigation systems, AGVs need space to make final adjustments before docking. If a workstation is placed too close to walls, machines, or storage racks, the AGV may not have enough room to align properly. This leads to repeated repositioning, which increases wear on the vehicle and reduces efficiency. Designing open buffer zones around docking points allows AGVs to correct alignment smoothly and reduces the chance of minor collisions or aborted tasks. The more complex the docking interaction—such as lifting, pushing, or roller transfer—the more important this spacing becomes.

Designing the Physical Structure of the Workstation

The physical structure of the workstation plays a major role in the AGV’s docking accuracy. Fixed stoppers, angled guides, and reinforced bump surfaces help the AGV settle into the correct position. Some factories use mechanical guides to “funnel” the AGV into place when high precision is required. The height and position of transfer points must match the AGV’s design, whether it uses lifting modules, conveyors, rollers, or towing hooks. In environments such as cleanrooms or precision assembly lines, surface materials must also be considered to avoid wear or contamination.

Sensor Calibration and Environmental Stability

AGVs rely heavily on sensors to perform accurate docking. These sensors interpret the surrounding environment, detect markers or features, and determine when the vehicle has reached the correct position. When lighting conditions fluctuate or when stations become cluttered with tools, boxes, or pallets, docking accuracy can be affected. Keeping the workstation environment clean and visually consistent helps ensure reliable sensor performance. Regular calibration is also important, especially when docks use vision-based systems or QR markers for positioning.

Avoiding Congestion and Minimizing Waiting Time

A workstation is only efficient if AGVs can access it without delay. If too many AGVs attempt to use the same docking point, traffic jams occur and the system slows down. Designing multiple access routes or distributing the workload across several stations helps reduce congestion. In high-throughput facilities, it may be necessary to create dedicated inbound and outbound areas so AGVs do not block each other. Traffic management software also plays a role, but good physical design minimizes the risk of vehicles waiting in line.

Designing for Operator and Human Interaction

Many AGV docking stations involve some level of interaction with human operators. This may include placing materials, removing completed goods, or pressing start and confirmation buttons. Workstations must therefore be comfortable and intuitive for operators to use. Clear lines of sight, safe distances, and ergonomic access points help prevent workplace injuries and ensure smooth cooperation between humans and AGVs. It is also important to avoid placing operator tasks in the AGV’s direct path to reduce unnecessary stops.

Supporting Future Expansion and Adaptability

Factories evolve over time, and AGV workstations should be designed with flexibility in mind. Modular station components, adjustable guides, and movable fixtures allow companies to update workflows without rebuilding the entire docking area. Designing stations for multiple AGV types—such as standard models, heavy-duty versions, or AGVs with different lifting heights—provides long-term scalability. Flexible design helps ensure that the docking infrastructure remains relevant as production needs grow.

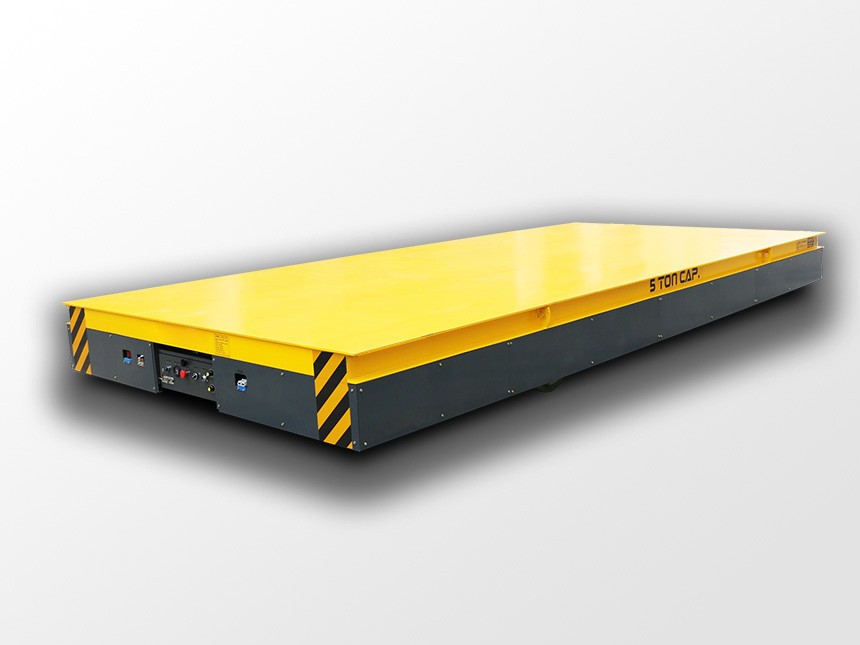

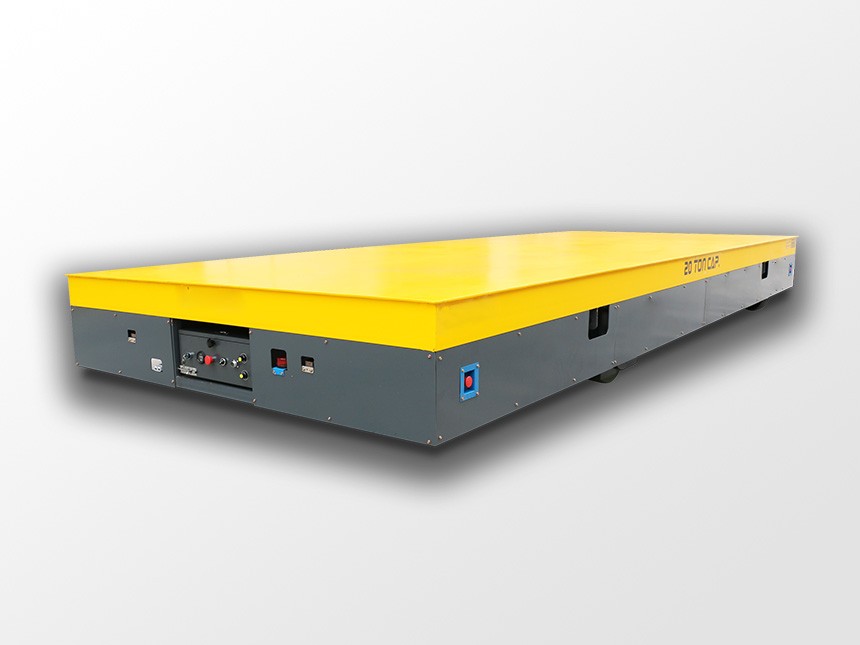

ATN Expertise in AGV Docking and Workstation Engineering

ATN offers comprehensive engineering services for AGV workstations and docking points. Our design team evaluates the customer’s workflow, space constraints, load types, and production takt time before creating customized docking solutions. Whether the application requires high-precision lifting, conveyor-to-vehicle transfer, robotic integration, or heavy-duty transport, ATN ensures reliable docking performance backed by real-world deployment experience across more than 48 countries.

More details are available at: https://www.atnagv.com

Conclusion

Well-designed AGV workstations and docking points form the foundation of an efficient internal logistics system. They determine how quickly materials can be transferred, how accurately AGVs can perform their tasks, and how stable the production flow remains. By focusing on alignment, approach paths, physical structure, operator interaction, and future scalability, manufacturers can build docking systems that support high productivity and long-term automation success.

As AGVs continue to expand across industries, thoughtful workstation design will remain essential for maximizing efficiency and ensuring seamless integration with modern manufacturing systems.

English

English 简体中文

简体中文