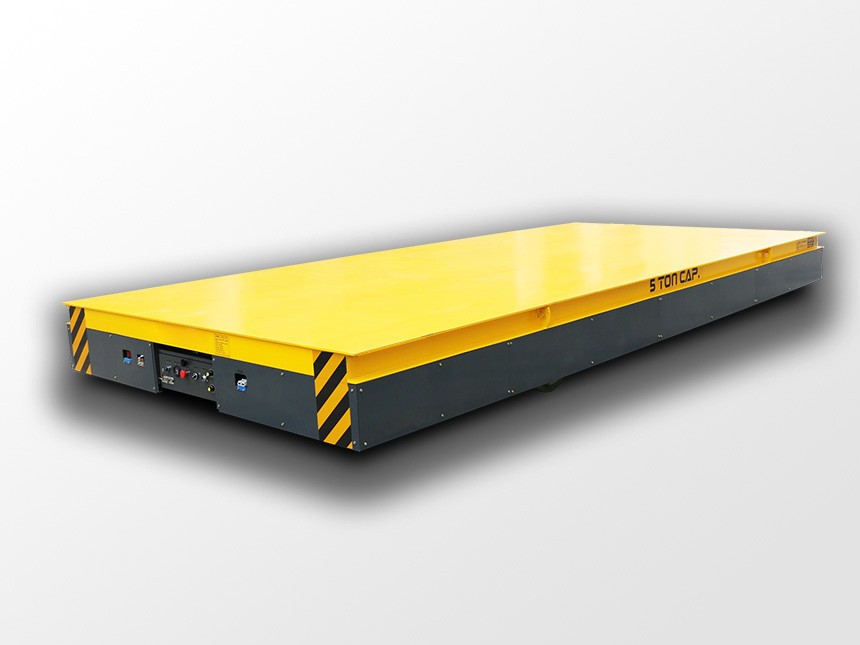

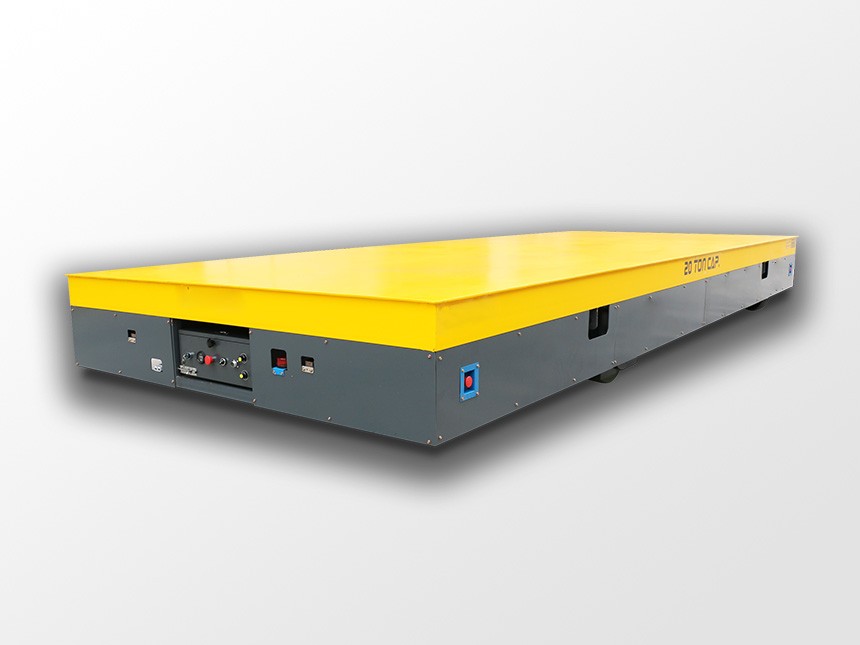

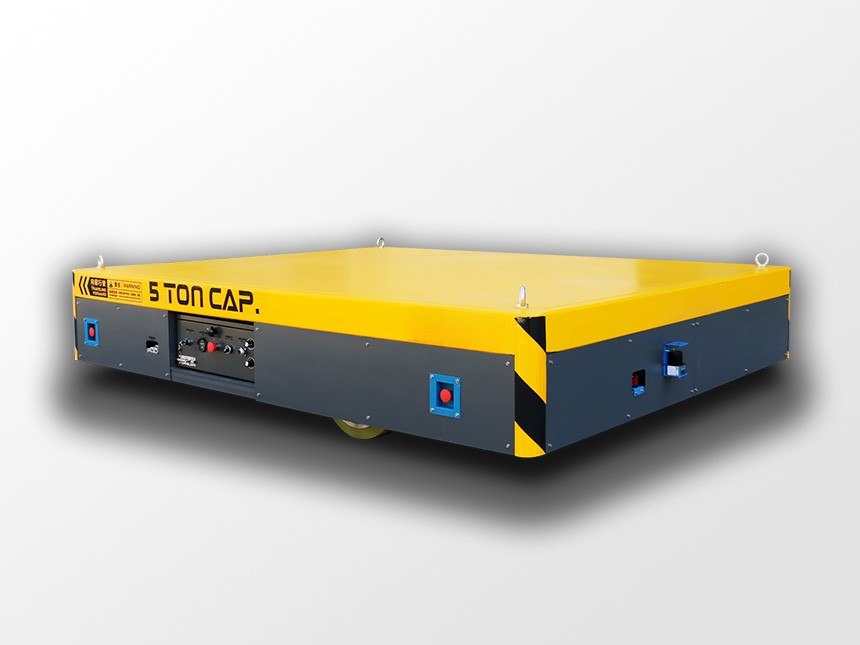

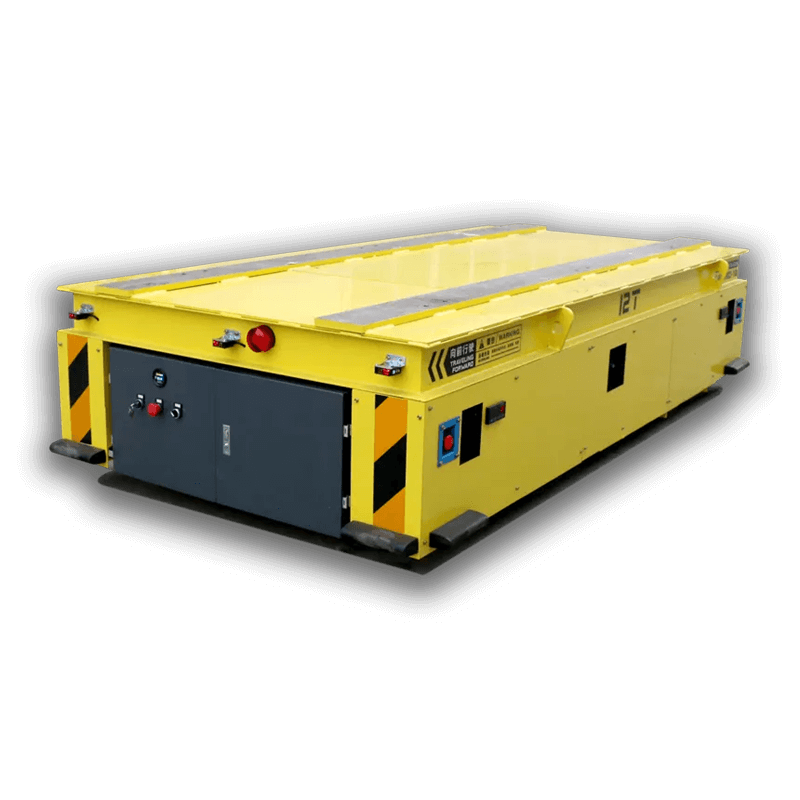

In heavy manufacturing sectors such as steel fabrication, energy equipment, and large machinery assembly, 100-ton electric transfer carts have become a common solution for internal material handling.

However, as component size and integration level continue to increase, many engineering teams now face a critical question during project planning:

Should the load capacity be upgraded to 150 tons or even 200 tons?

This decision is not simply about increasing rated load. In practice, it defines the technical boundary of structure design, drive system capability, control accuracy, and long-term operational reliability.

Based on extensive project experience, Xinxiang Aotenen has found that the transition from 100 tons to 200 tons represents a clear engineering threshold rather than a linear upgrade.

Load Upgrade Challenges: Stability Matters More Than Maximum Pulling Force

In real industrial environments, the primary challenge of a heavy-duty electric transfer cart does not occur at startup.

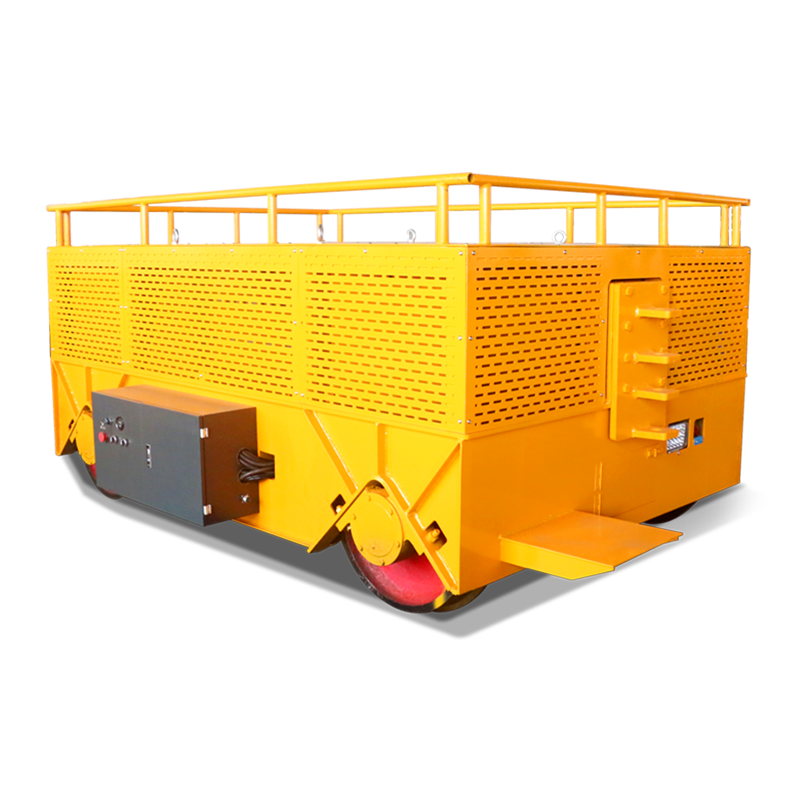

It emerges during continuous operation under full load, frequent starts and stops, and complex movement paths.

When payload increases from 100 tons to 200 tons, three critical issues become dominant:

Wheel load concentration, placing higher demands on floor or rail structure

Inertial forces during acceleration and turning, increasing fatigue stress on the chassis

Reduced tolerance for positioning errors, especially during assembly or docking operations

This explains why simply increasing motor power or steel thickness does not guarantee reliable performance.

Core Technical Principle: How 200-Ton Electric Transfer Carts Remain Controllable

At the 200-ton level, electric transfer carts (also known as heavy-duty transfer carts or industrial transport platforms) rely on load distribution and coordinated control, rather than brute force.

Key technical measures include:

Multi-wheel load-sharing structures, reducing single-wheel pressure

Low-speed, high-torque electric drive systems, ensuring smooth startup under full load

Closed-loop control with encoder feedback, maintaining synchronized motion and stable positioning

The objective is consistent: transform extreme weight into predictable and controllable movement.

Comparison with Traditional Handling Solutions

Some facilities still attempt to use forklifts or towing systems for heavy components. These solutions quickly reach their limits beyond 100 tons.

| Aspect | Forklift / Towing Combination | 200-Ton Electric Transfer Cart |

|---|---|---|

| Load stability | Difficult to balance | Structured load distribution |

| Positioning accuracy | Operator-dependent | ±5–10 mm achievable |

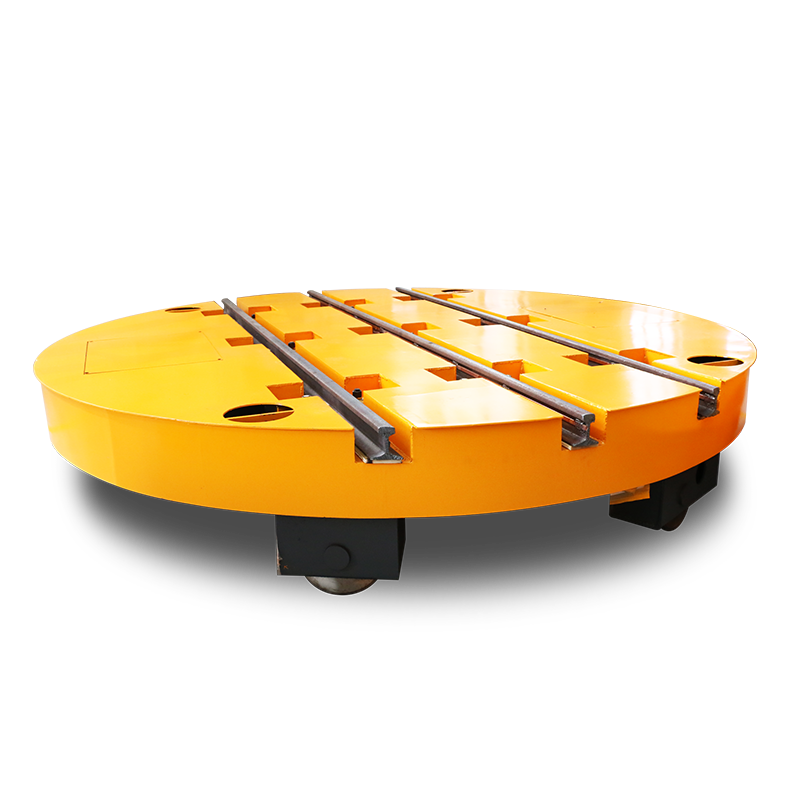

| Narrow aisle operation | Large turning radius | 360-degree omnidirectional movement |

| Long-term reliability | High wear and risk | Designed for continuous duty |

For heavy load and confined-space operations, electric transfer carts offer a significantly more controllable and safer solution.

Industry Application Example 1: Steel Structure Manufacturing

Problem

Large steel beams and modules often exceed 120 tons, while workshop aisle width remains limited.

Solution

A 200-ton battery-powered electric transfer cart enables lateral movement and in-place rotation, eliminating the need for additional turning space and structural modification of the workshop.

Industry Application Example 2: Energy Equipment Assembly

Problem

Heavy components require precise alignment before lifting or final assembly.

Solution

Electric transfer carts equipped with low-speed control modes (5–10 m/min) provide high positioning accuracy under full load, improving safety and assembly efficiency.

Understanding the Real Load Capacity Boundary

From an engineering perspective, 200 tons is not the absolute maximum achievable load.

However, it represents a balanced point between cost, reliability, and versatility.

Beyond this range, projects typically require:

Reinforced foundations or special rail systems

Increased customization and validation cycles

Higher cost with reduced flexibility

For this reason, Xinxiang Aotenen emphasizes application-driven load selection rather than numerical escalation.

English

English 简体中文

简体中文